NEW! SERIES 2023-24

“…it was very cold, we were in a perfectly closed room: windows, doors and any opening were totally closed and we had no humidity problem. It is really true: the tent fabric is like the highly breathable fabric of our jackets. Maggiolina is in our opinion the best product and we recommend it, absolutely! Bye Bye.”

“Up on a gorge with panoramic view on a glacier or in front of an elk weighing 4500 kilograms close to a stream, there are always good reasons to stop and camp. The important thing is to have a Maggiolina. The right product for any situation. Kind regards to everybody”

“Since 1997 Autohome roof tents are the most reliable bedrooms we have been sleeping in. In any weather condition, we always have a wonderful and comfortable bed, ready in a couple of minutes.”

“I felt I had to congratulate Autohome. I bought an Airlander and 2 days in the humidity of the woods made me appreciate the perfection of my future home for the week-ends and for the vacations all around the Alps.”

✓ Overland and Overzone are available today with an ALL-SEASON opening roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

✓ The useful protective pre-entry, ideal in case of bad weather, becomes standard. The transparent Crystal panels supplied with the tent, strictly removable, allow you to enjoy the view while it rains outside.

✓ The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric is used, in a toned down black colour for Overland and Olive Green for Overzone, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

✓ Overland and Overzone are fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

✓ Technical reasons as lead to the selection of these colours. The double-sided black roof and the Carbon colour on the walls do not filter the first lights of the day.

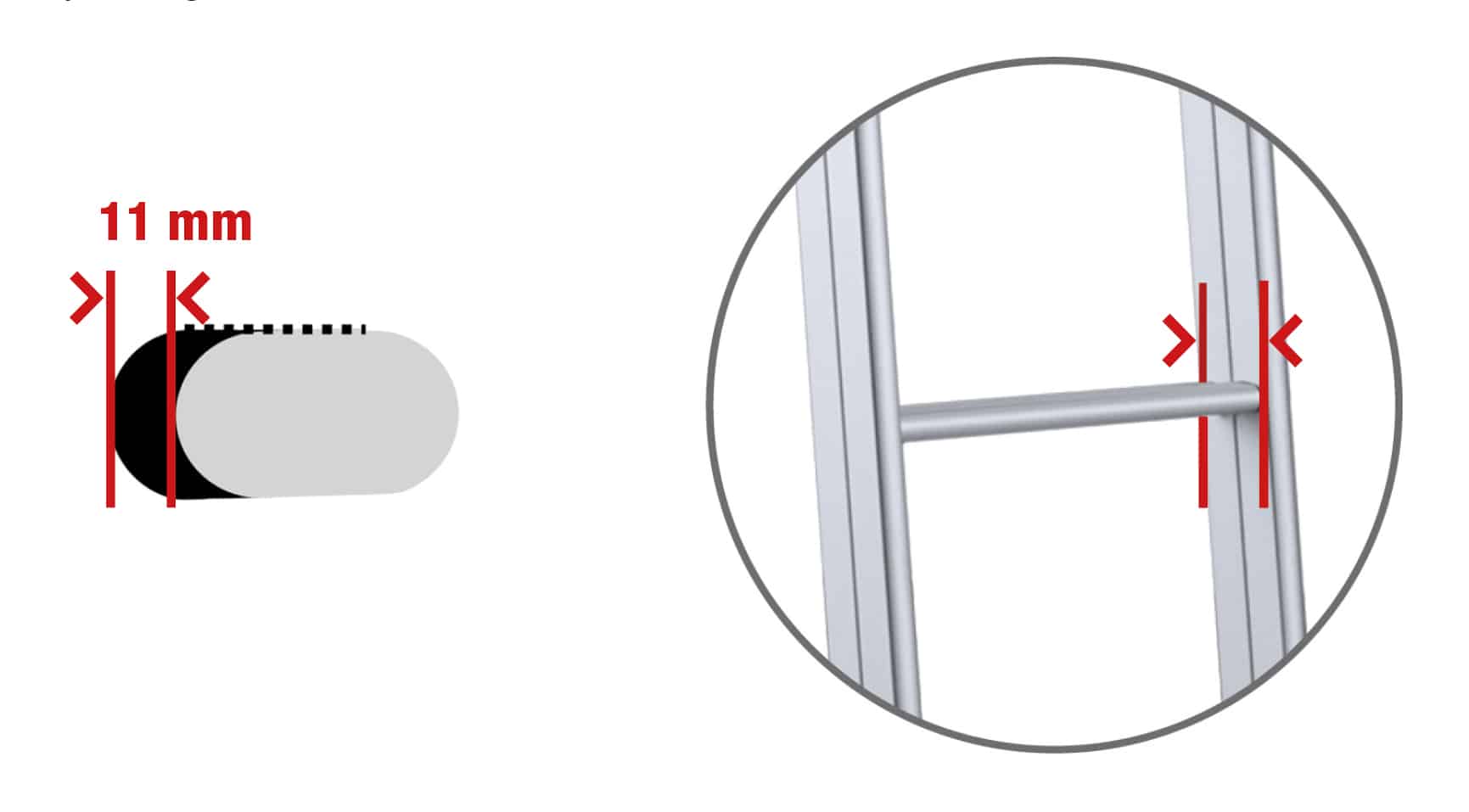

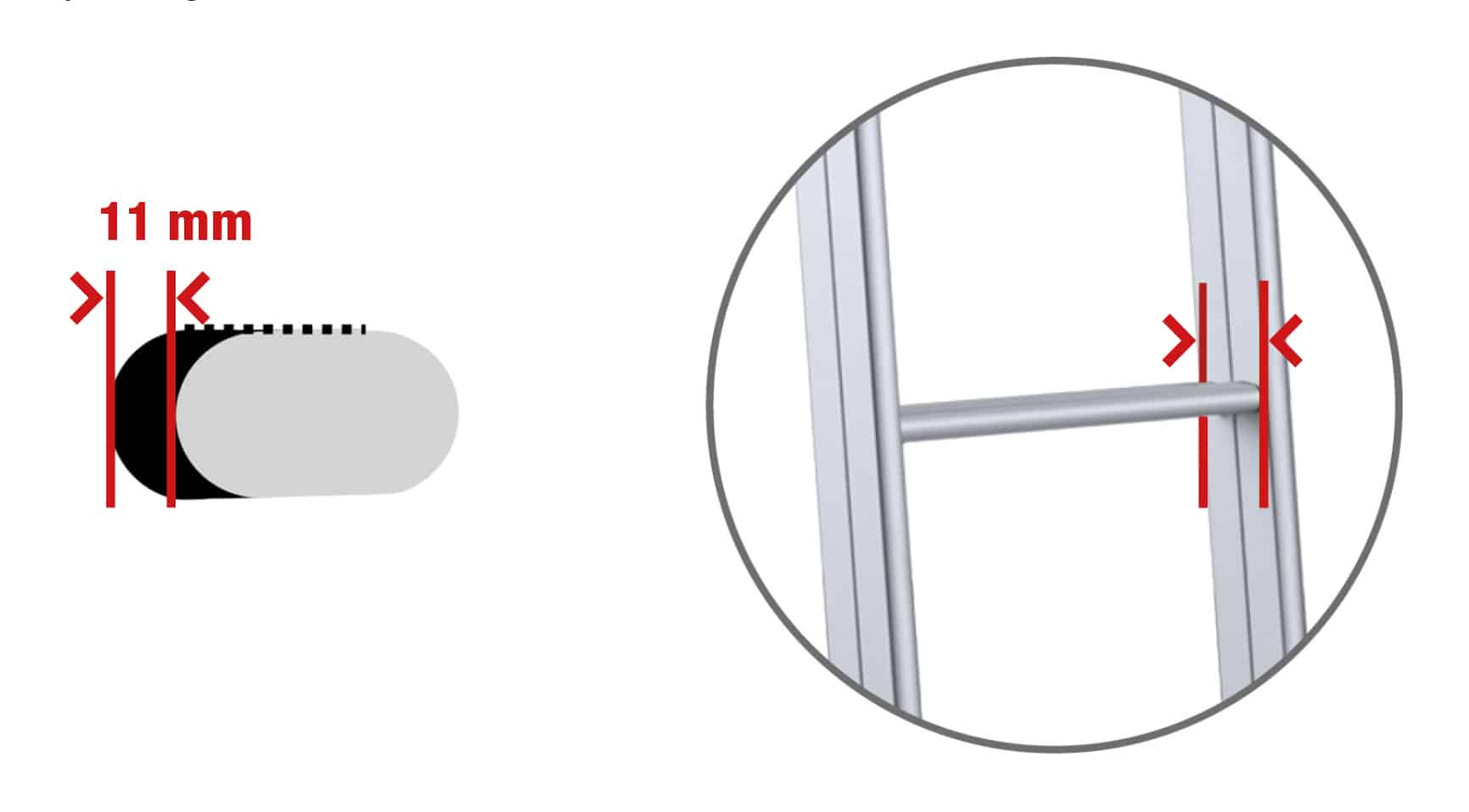

✓ A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

✓ It is the fundamental element to sleep well.

To decide what to offer, Autohome specialists tested different solutions and carried out different tests. The market offers multiple proposals: coupled sponge rubbers, shaping rubbers, layered rubbers, shaped rubbers, massage solutions and even extravagant. But Autohome choosed only the best, to satisfy even the most demanding customer.

✓ All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

✓ Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

✓ The ladder was redesigned to achieve the best goals of functionality, reliability, and comfort.

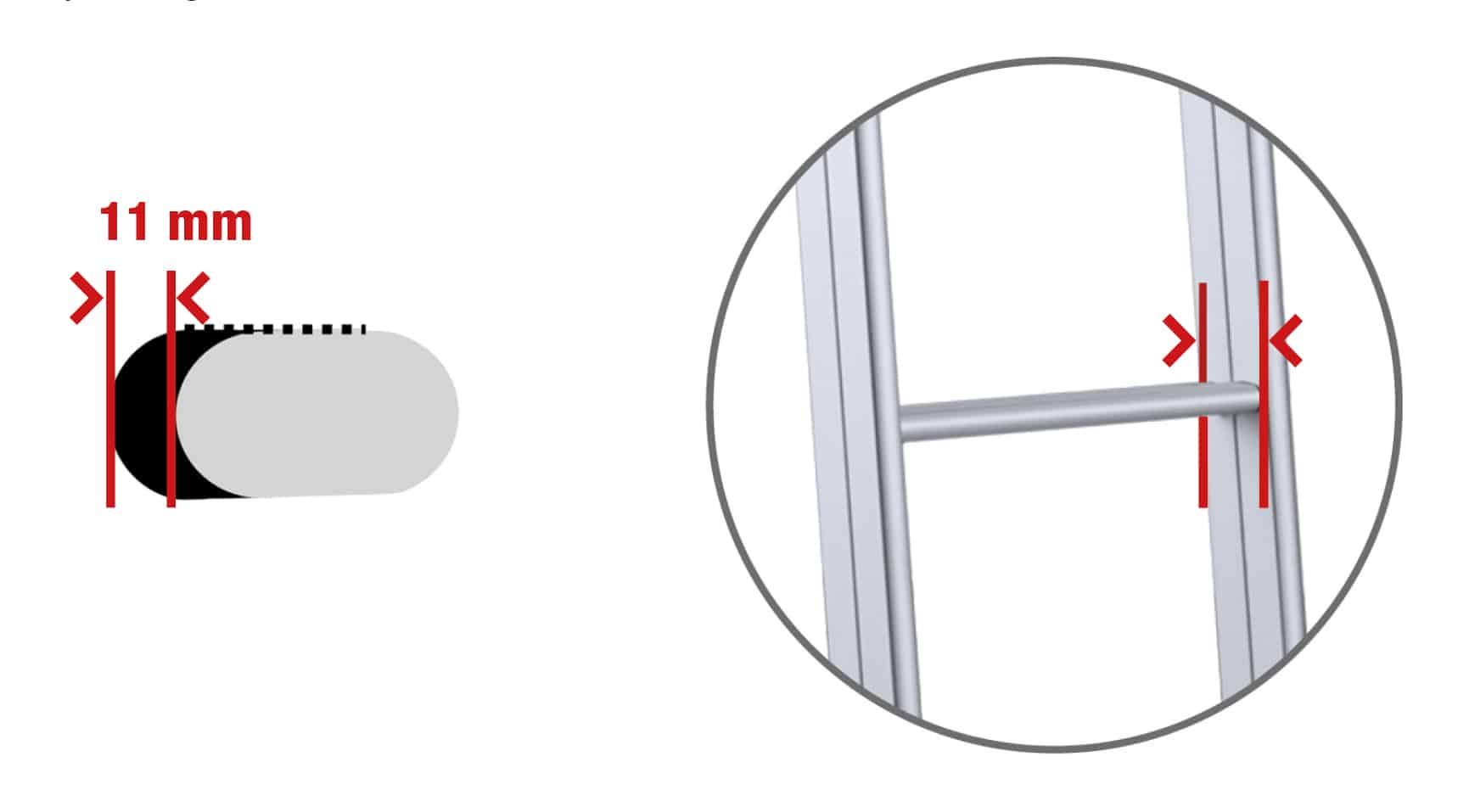

First, it is made of stainless steel (a material, a certainty!), with wide wooden steps. Especially designed with minimum thickness uprights, it remains housed above the closed tent without deforming the cover. Designed and manufactured specifically for the Autohome tents. Nothing comparable to the low-cost roof tents not specific to this field of application.

– The ladder is an integral part of the frame, this is directly connected to the backbone of the tent (i.e. to the hinging of the two halves of the planes) by 2 omega support profiles placed diagonally, so as to better distribute the weight of the occupants. The result is: less flexions, more resistance, more stability and reduced thickness to a minimum.

A patent born in Autohome that since 1958 many tried to imitate, without success. Its uniqueness is the result of several interrelated factors:

– It is always ready and easily deployed.

– It is designed with a ladder block, to avoid slipping on slippery ground or floors.

– EASY USE telescopic adjustment is a very reliable smart solution, that has made the history of the roof tent. It is easy to adjust and is always functional.

– The ladder can be quickly extended to fit any height, within its maximum length of 2.30 m

– Compact and linear, it does not generate protrusions or malformations to the cover when the tent is closed while travelling.

– It is fitted with sturdy wooden steps, waterproof and water-repellent. Elegant, natural and of pleasant design, they offer a wide non-slip support. They also do not warm up in the sun and thus always allow you to climb barefoot.

Our Cover is even more sturdy.

A solidity which is the result of specific choices, starting from the materials: 600Gr/sqm PVC with 900gr/sqm reinforcements in the most stressed points. A solidity enhanced by a special shaping with internal seams, more resistant than normal welding. More precisely, they do not fall apart. A synergy to withstand even the highest climatic temperatures and offer superior aerodynamic stability.

With a regular parallelepiped shape, our covers have slightly rounded corners to enhance stability and safety, so they do not require upper ties with visible straps, affecting the tent aesthetics of the tent. The result is a clean and tidy line, to always travel with style.

Drawing on the experience of the most performing commercial vehicles, such as big lorries and curtain-sided trucks, Autohome covers also use a perimetral adjustable elastic rope for binding, in order to compensate for any expansion of the materials due to weather conditions: the cover remains well-fitted to the tent, without any zipper.

A choice of reliability made in 1958 and always confirmed, considering also that the elastic rope is easy to replace. 6mm in diameter and variable length according to the perimeter or model of the tent. The coupling and the regulation are carried out by two carabiners placed at the ends. Today the coupling and uncoupling is easier even when the tent is fixed on the roof bars or on baggage racks, thanks to the special tool supplied together with the cover.

This practicality is appreciated in every condition: you will have no problem in case of unfastening or coupling even in the desert, in marshy areas, on muddy roads, in the presence of foliage and shrubs, because the elastic tie rod always works and will never fail.

The quality of our cover is branded with the Autohome logo on the 110 cm short side, while on the long side there is a label representing the legendary paths of Nino Cirani. Black was chosen for the colour: always elegant and anti-stain.

✓ Overland and Overzone are available today with an ALL-SEASON opening roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

✓ The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric is used, in a toned down black colour for Overland and Olive Green for Overzone, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

✓ Overland and Overzone are fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

✓ Technical reasons as lead to the selection of these colours. The double-sided black roof and the Olive colour on the walls do not filter the first lights of the day.

✓ A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

✓ All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

✓ Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

✓ It is the fundamental element to sleep well.

To decide what to offer, Autohome specialists tested different solutions and carried out different tests. The market offers multiple proposals: coupled sponge rubbers, shaping rubbers, layered rubbers, shaped rubbers, massage solutions and even extravagant. But Autohome choosed only the best, to satisfy even the most demanding customer.

✓ The ladder was redesigned to achieve the best goals of functionality, reliability, and comfort.

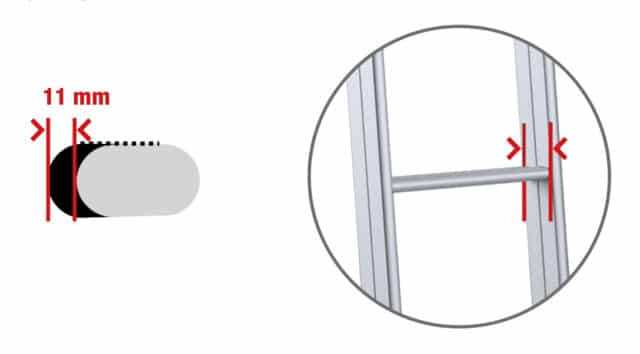

First, it is made of stainless steel (a material, a certainty!), with wide wooden steps. Especially designed with minimum thickness uprights, it always remains housed above the closed tent without deforming the cover. Designed and manufactured specifically for the Autohome tents. Nothing comparable to the low-cost roof tents not specific to this field of application.

– The ladder is an integral part of the frame, this is directly connected to the backbone of the tent (i.e. to the hinging of the two halves of the planes) by 2 omega support profiles placed diagonally, so as to better distribute the weight of the occupants. The result is: less flexions, more resistance, more stability and reduced thickness to a minimum.

A patent born in Autohome that since 1958 many tried to imitate, without success. Its uniqueness is the result of several interrelated factors:

– It is always ready and easily deployed.

– It is designed with a ladder block, to avoid slipping on slippery ground or floors.

– EASY USE telescopic adjustment is a very reliable smart solution, that has made the history of the roof tent. It is easy to adjust and is always functional.

– The ladder can be quickly extended to fit any height, within its maximum length of 2.30 m

– Compact and linear, it does not generate protrusions or malformations to the cover when the tent is closed while travelling.

– It is fitted with sturdy wooden steps, waterproof and water-repellent. Elegant, natural and of pleasant design, they offer a wide non-slip support. They also do not warm up in the sun and thus always allow you to climb barefoot.

Our Cover is even more sturdy.

A solidity which is the result of specific choices, starting from the materials: 600Gr/sqm PVC with 900gr/sqm reinforcements in the most stressed points. A solidity enhanced by a special shaping with internal seams, more resistant than normal welding. More precisely, they do not fall apart. A synergy to withstand even the highest climatic temperatures and offer superior aerodynamic stability.

With a regular parallelepiped shape, our covers have slightly rounded corners to enhance stability and safety, so they do not require upper ties with visible straps, affecting the tent aesthetics of the tent. The result is a clean and tidy line, to always travel with style.

Drawing on the experience of the most performing commercial vehicles, such as big lorries and curtain-sided trucks, Autohome covers also use a perimetral adjustable elastic rope for binding, in order to compensate for any expansion of the materials due to weather conditions: the cover remains well-fitted to the tent, without any zipper.

A choice of reliability made in 1958 and always confirmed, considering also that the elastic rope is easy to replace. 6mm in diameter and variable length according to the perimeter or model of the tent. The coupling and the regulation are carried out by two carabiners placed at the ends. Today the coupling and uncoupling is easier even when the tent is fixed on the roof bars or on baggage racks, thanks to the special tool supplied together with the cover.

This practicality is appreciated in every condition: you will have no problem in case of unfastening or coupling even in the desert, in marshy areas, on muddy roads, in the presence of foliage and shrubs, because the elastic tie rod always works and will never fail.

The quality of our cover is branded with the Autohome logo on the 110 cm short side, while on the long side there is a label representing the legendary paths of Nino Cirani. Black was chosen for the colour: always elegant and anti-stain.

✓ Large window designed to offer an excellent view, but above all great privacy. When open, it assures the right privacy and cosiness.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ The size of the shells is confirmed, so their capacities are unchanged. While in the Large models they are reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

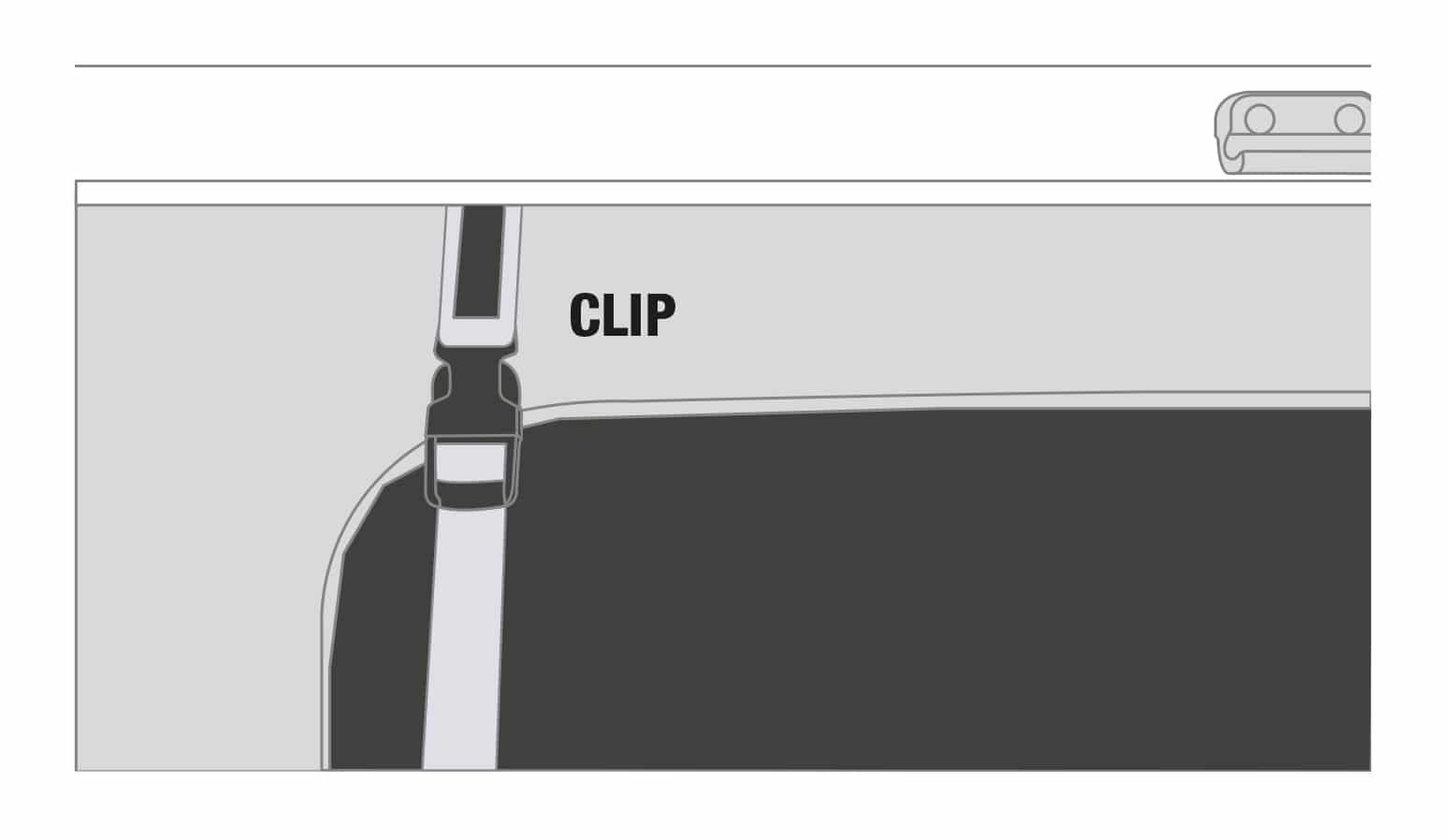

✓ Comfortable and adjustable element, firmly attached to the shell, it allows to lower the roof and facilitates the closing phase. Now it is also easily removable. An evolution which avoids noise in case of wind and reduces the overall dimensions. The roll clips of the back door can be locked by Velcro directly under the drip of the roof. The whole system is windproof.

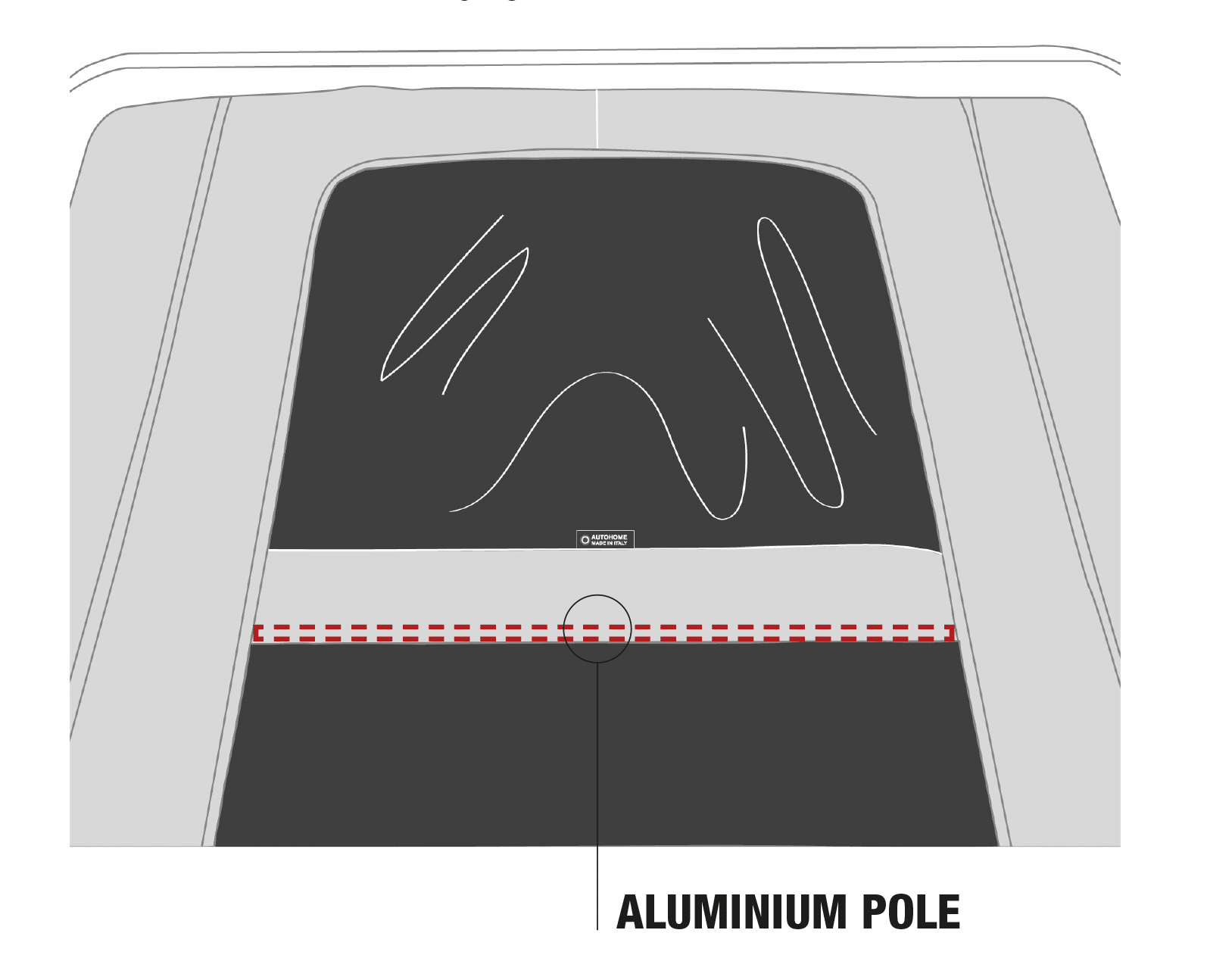

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved; the NATURE WHITE and BLACK STORM colours are confirmed.

It should be noted that the DOMESTIC WHITE colour of the basic models is running low.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ Colours of the AUTOHOME logo on the shells have been renewed: silver, black variant on demand on Black Storm models.

✓ The additional perimeter protection, ideal in bad weather, becomes from today a “standard” solution.

Wing means two prominent eaves on the side entrances, and a wide back protection. This self-supporting solution can be easily attached to the roof with Velcro and a modular arched pole.

The feeling of protected space and airiness is remarkable: an upgrade designed to increase attention and appreciation.

✓ Entirely redesigned, it offers even more functional and customizable solutions. The transparent glass PVC needs to be mentioned, allowing to see outside even in case of bad weather, which now become removable. The customised back door openings are supported by aluminium poles embedded in the fabrics, to counteract the negative effects of the wind.

✓ Comfortable and adjustable element, firmly attached to the shell, it allows to lower the roof and facilitates the closing phase. Now it is also easily removable. An evolution which avoids noise in case of wind and reduces the overall dimensions. The roll clips of the back door can be locked by Velcro directly under the drip of the roof. The whole system is windproof.

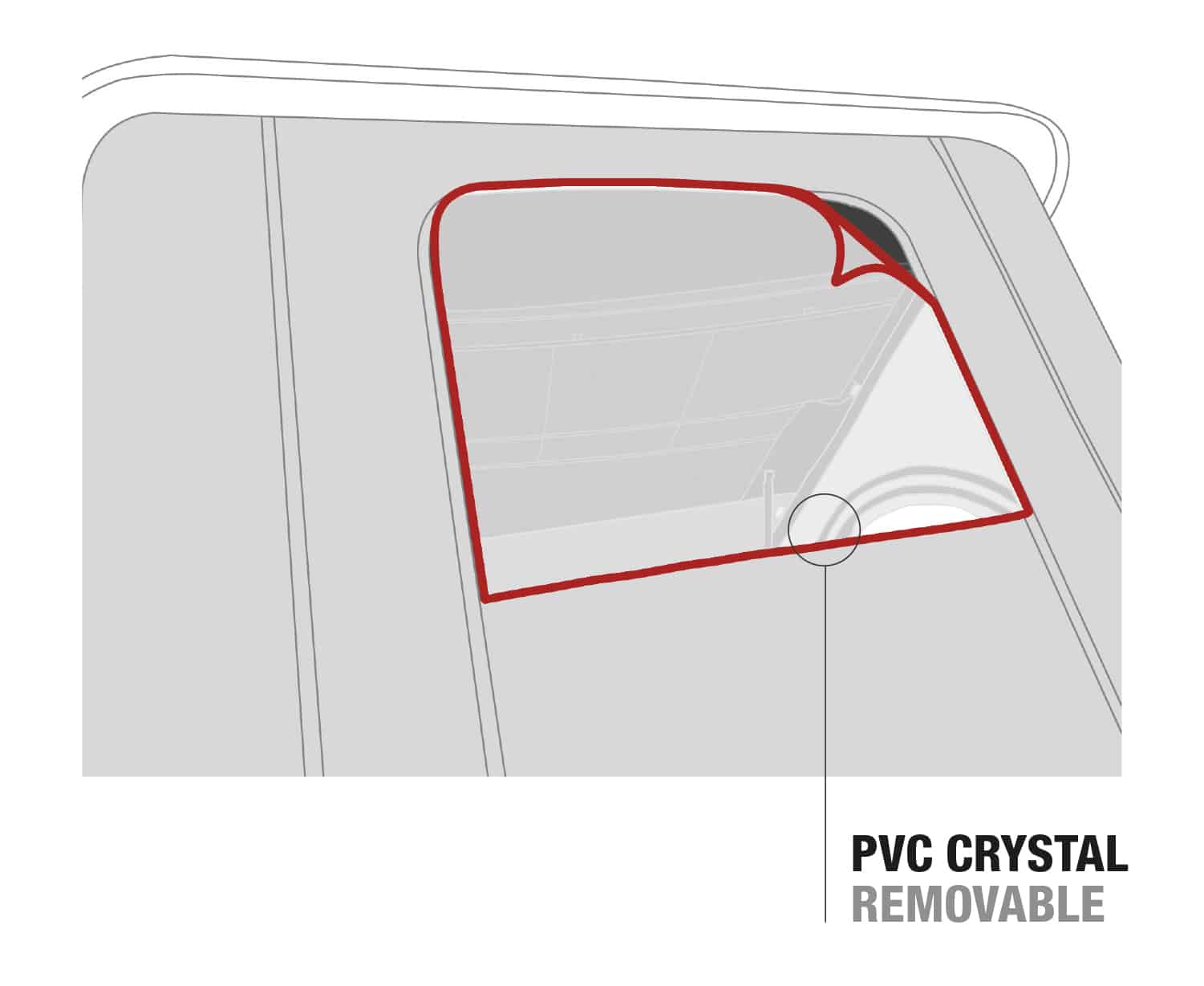

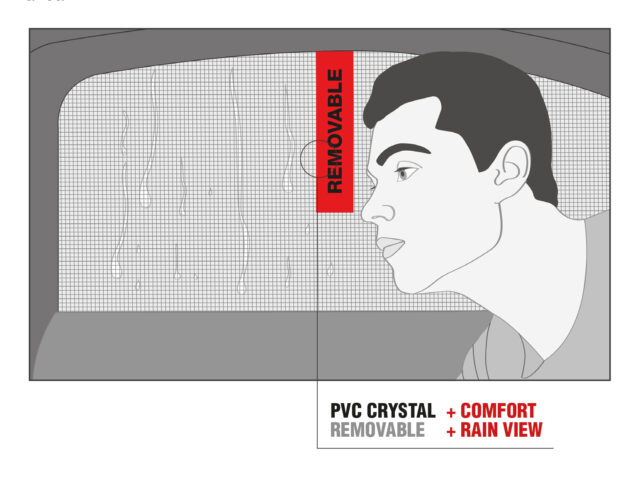

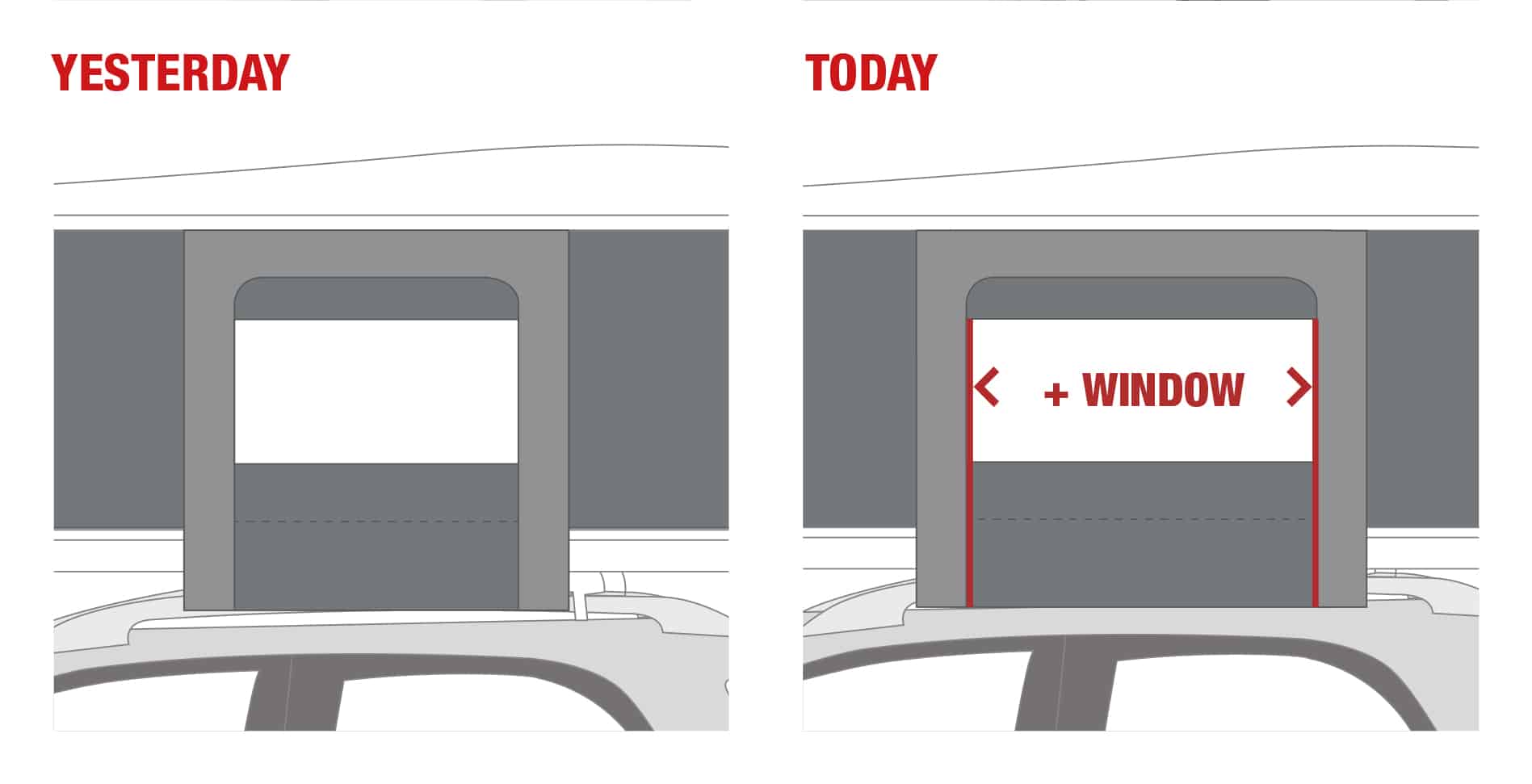

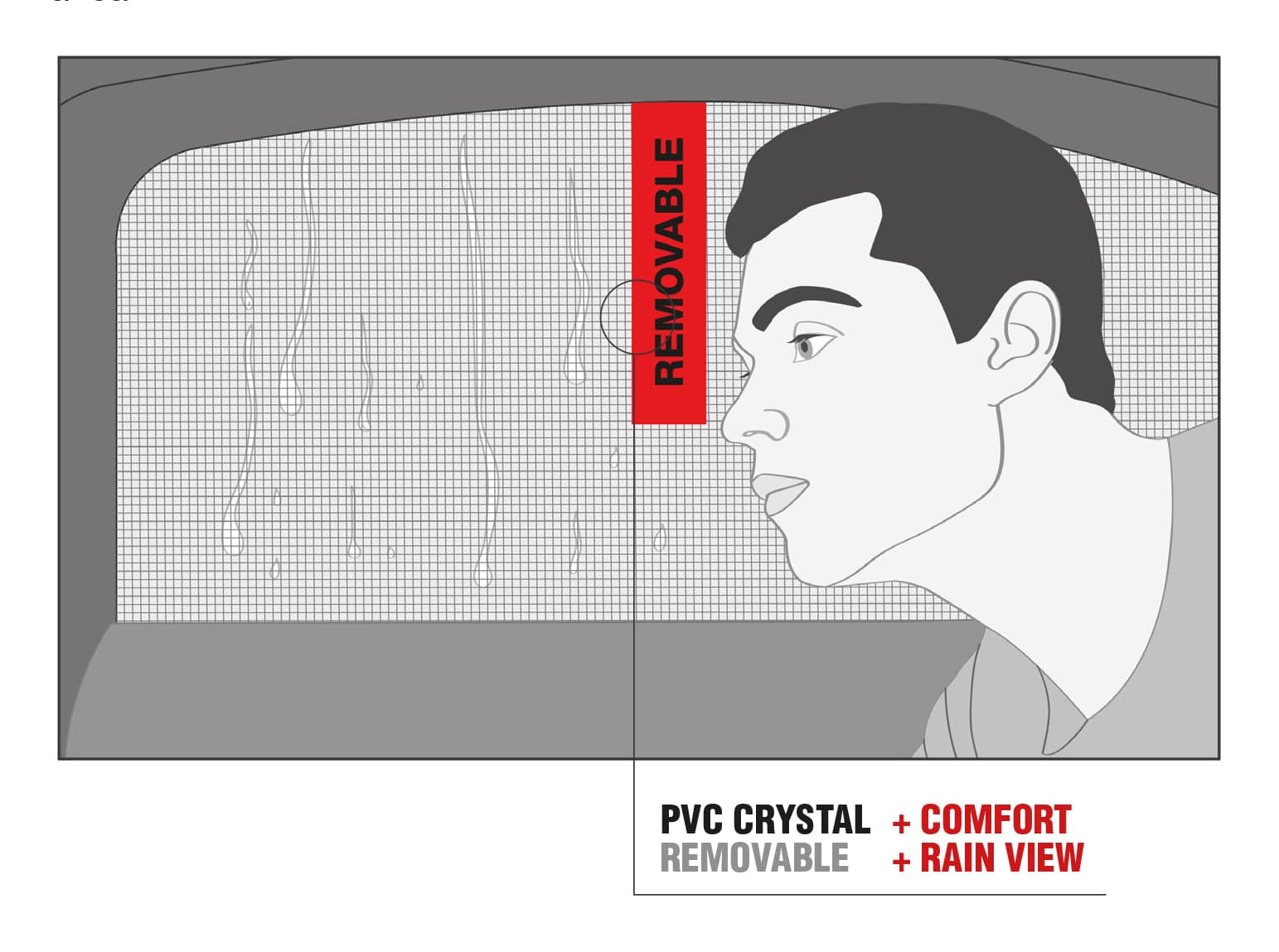

✓ A transparent PVC window allowing to see outside even in case of bad weather, always fixed and permanent, is now removable when needed. PVC can be a source of heat retention and condensation, so the fact that the window can be removed is very useful when environmental conditions lead to a high rate of humidity and heat, for example during the sultry summer nights, when the feeling of discomfort is accentuated by body evaporation.

The window, fitted in the upper part of the rear door, can be easily applied and removed thanks to the special Velcro.

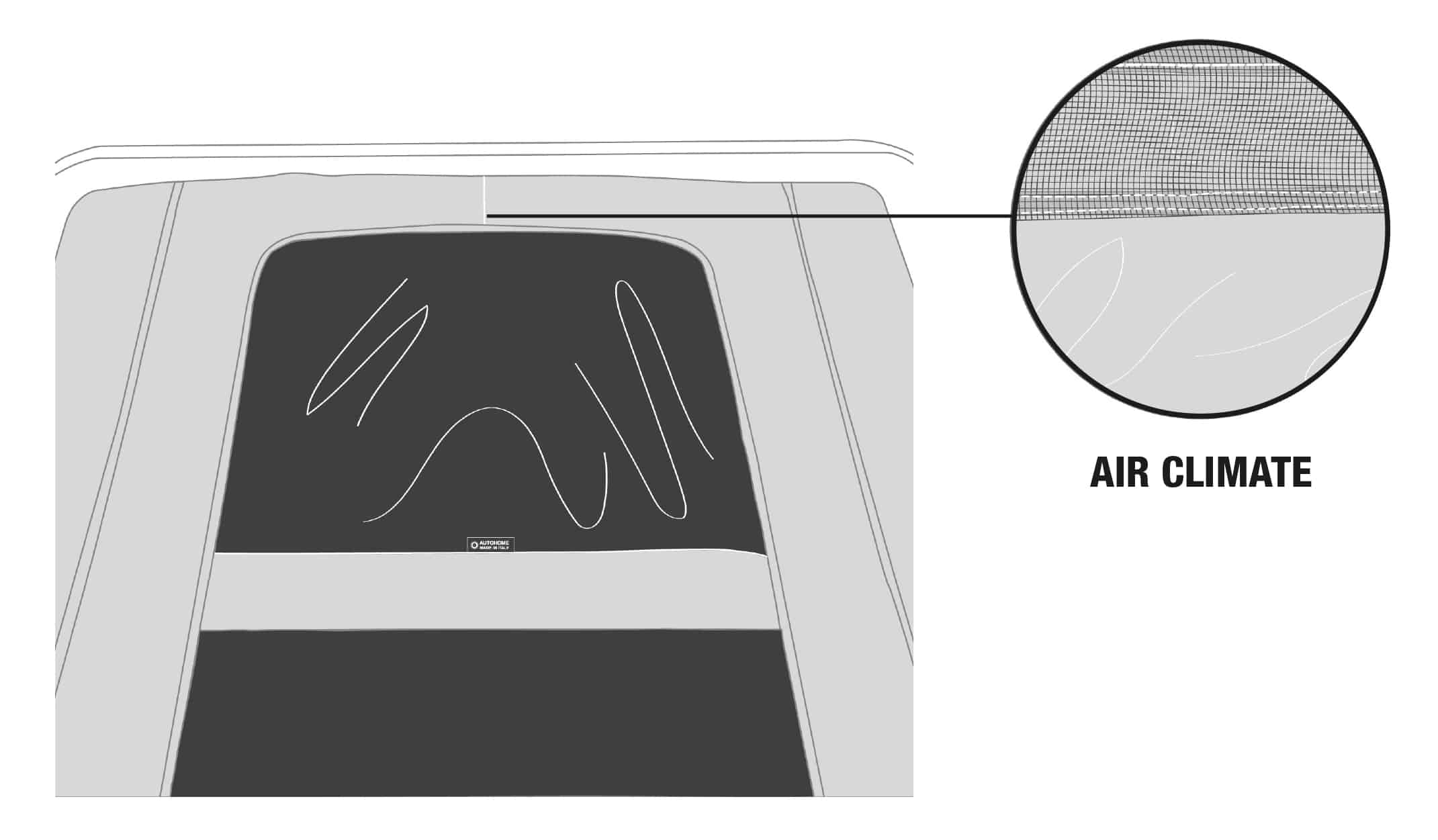

✓ The internal ventilation system, which is now called AIR CLIMATE, changes its appearance and size. It now has a wide opening in the upper part of the fabric, 80 cm wide, which efficiently and naturally promotes air exchange.

✓ A new solution applied to the inner ceiling, equipped with closeable pockets to prevent objects and other materials falling.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ The size of the shells is confirmed, so their capacities are unchanged. While in the Large and X-LARGE models they are reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved; the NATURE WHITE and BLACK STORM colours are confirmed.

It should be noted that the DOMESTIC WHITE colour of the basic models is running low.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ Colours of the AUTOHOME logo on the shells have been renewed: silver, black variant on demand on Black Storm models.

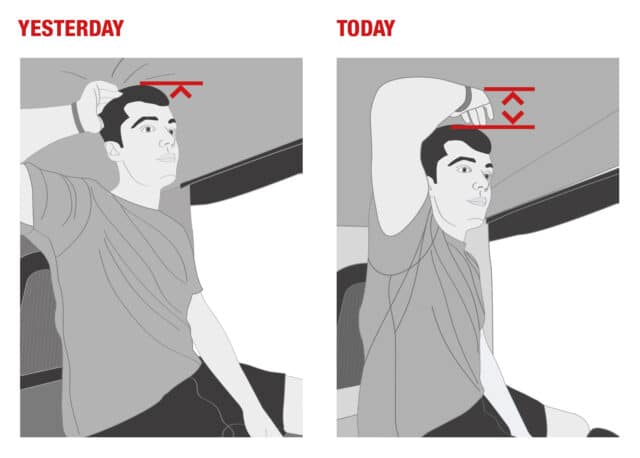

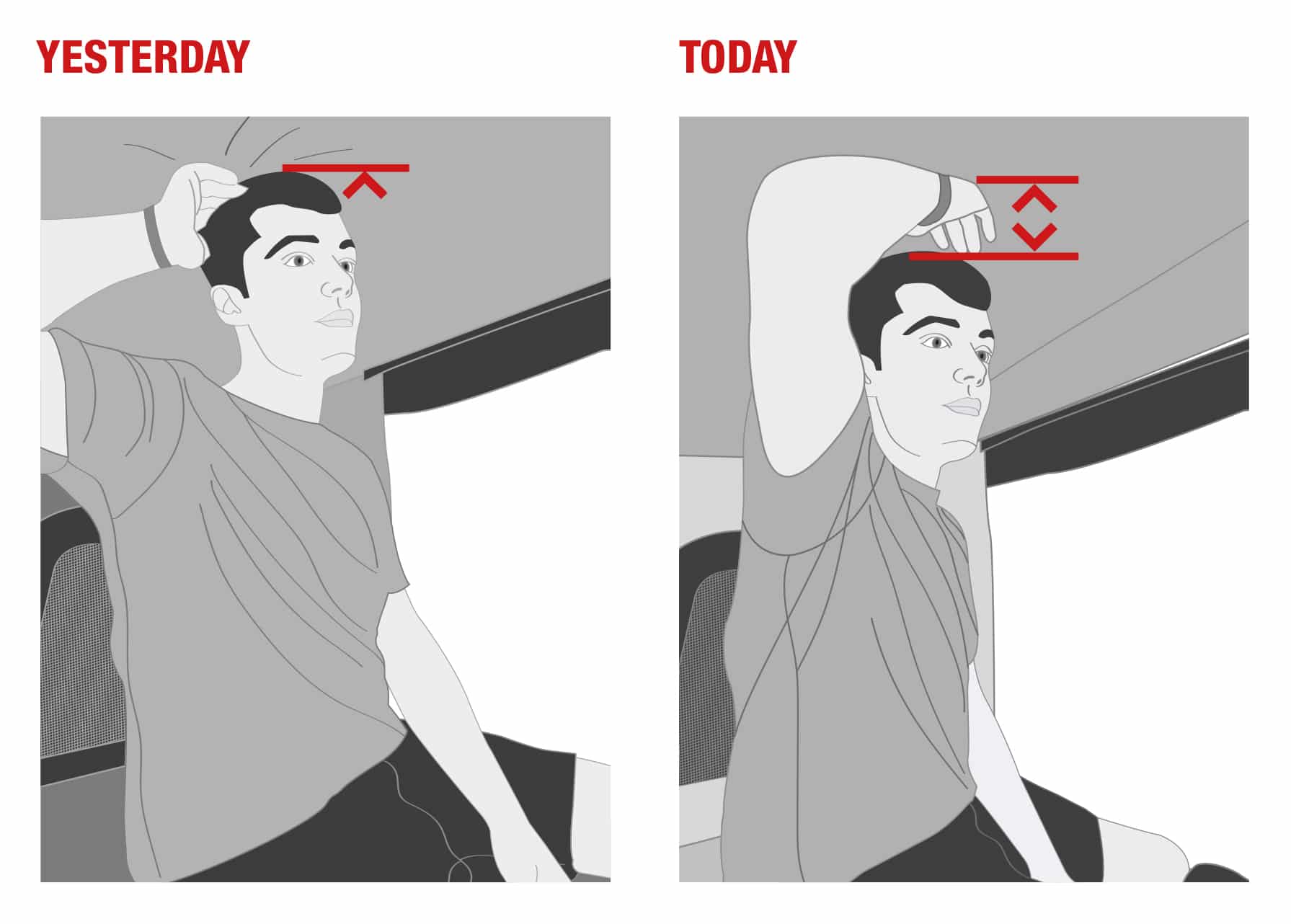

✓ All Maggiolina and Airtop tent models, when opened, now have a higher height. An important upgrade, which does not change the natural stability that is an integral part of the success of these tents.

✓ Increasing the internal height, the comfort of the product changes significantly: the raised roof of the new series, allows you to stay agile, having easy motions even while sitting in the tent. The feeling of space and airiness is really unique.

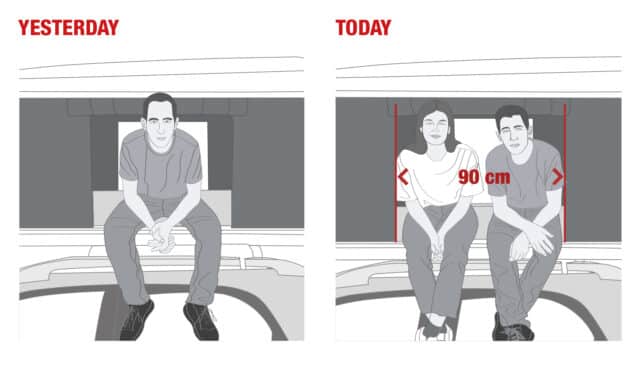

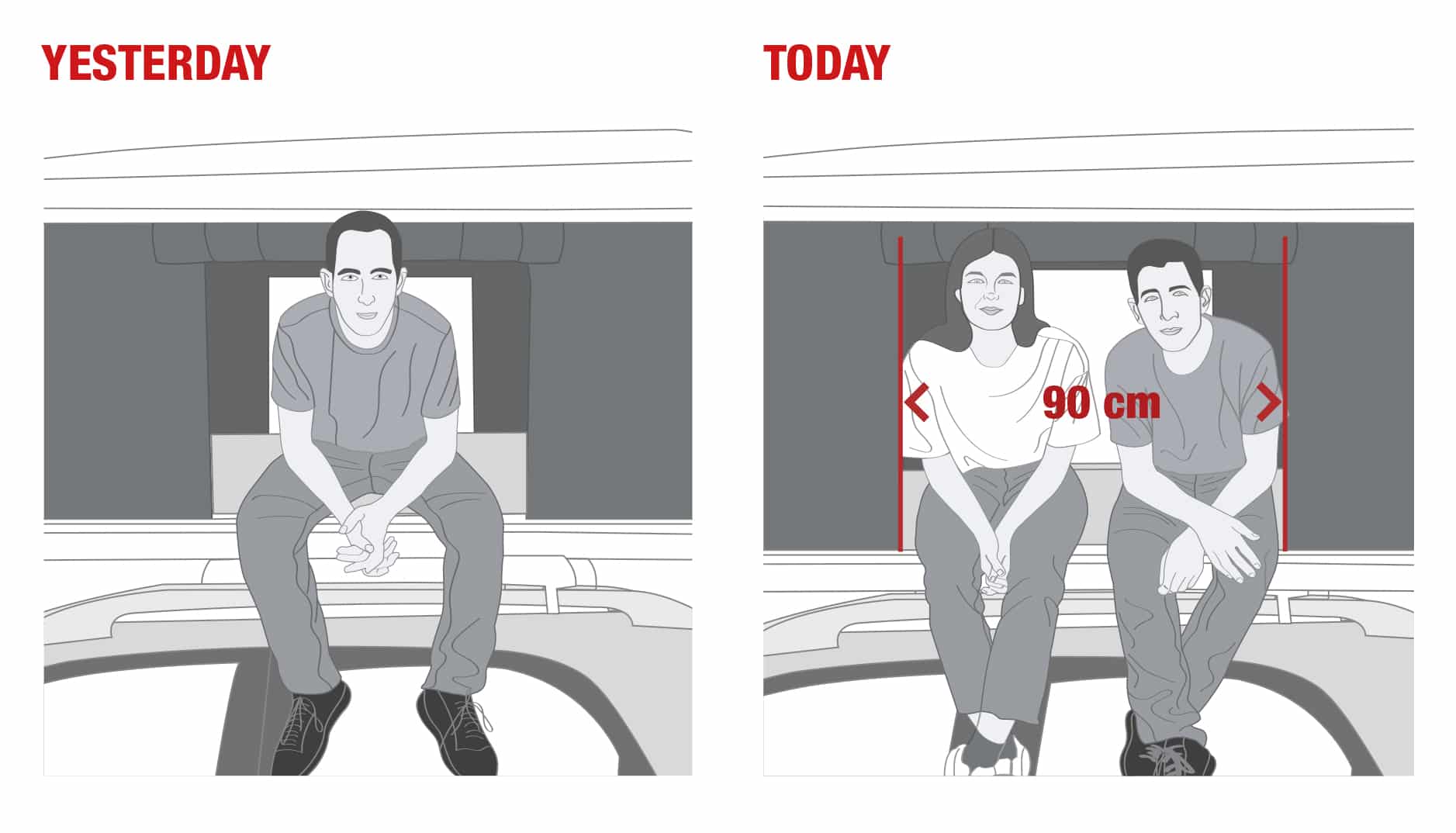

✓ The doors are even larger; 90 cm. The tent becomes even more welcoming and functional, as well as offering the advantage of facilitating the moments of dressing and undressing. It should also be noted that these wide openings are easily transformed into large windows with a custom opening.

✓ A further opportunity: the 360 tent models are fitted with transparent PVC glass protections to see outside even in case of bad weather. Both on the right and left side of the tent you have a great view. Of course, the Crystal protections are removable in case of intense humidity and heat. This new feature makes the 360 models even more pleasant to live in all weather conditions.

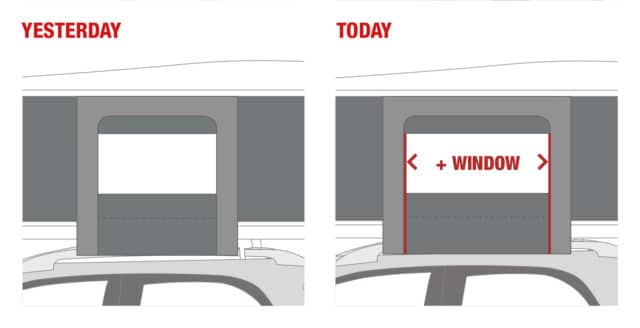

✓ The principle of greater livability (+ livability + airiness) also characterizes the windows, thanks to larger dimensions, without affecting privacy.

✓ The 360 models are fitted with a removable transparent Crystal protection. These windows are not permanent on the tent, they can be sources of heat and condensation, even when simply rolled up. That is why they are fitted with Velcro that makes them easily and totally removable when necessary. The tents are provided with a flat bag for the windows which can be stored under the mattress.

✓ A new solution applied to the inner ceiling, equipped with closeable pockets to prevent objects and other materials falling.

✓ Better waterproof capacity, while the breathability remains almost unchanged, as it is an essential characteristic for Autohome.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ Based on their excellent functionality, the size of the shells and their capacities are confirmed. While for the Large and X-LARGE models the shells have been reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved. The NATURE WHITE and BLACK STORM colours have been confirmed.

The Extreme Series is confirmed only in the Black Storm version.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ The new device is adopted, which blocks the glass of the upper window when it is completely open at 90°.

✓ A special protection is now available, valuable in the event of incorrect closing manoeuvres by the user.

✓ Colours of the AUTOHOME logo on the shells have been reviewed: bronze on the models with a crank opening, silver for the models with gas springs opening. Black variant on demand on Black Storm models.

Overcamp is available today with an ALL-SEASON roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

The useful protective pre-entry, ideal in case of bad weather, becomes standard. The transparent Crystal panels supplied with the tent, strictly removable, allow you to enjoy the view while it rains outside.

The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric, in GRAY colour, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

Overcamp is fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

Technical reasons as lead to the selection of these colours. The double-sided black roof and the grey colour on the walls do not filter the first lights of the day.

A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

The SMALL (2 Places in Measurements 130 cm x 200) and LARGE (4 Places in Measurements 180 cm x 200) sizes are confirmed.

The section of the step was enlarged for a more comfortable support of the foot.

MORE NEWS AND DETAIL