NEW! SERIES 2023-24

✓ Overland and Overzone are available today with an ALL-SEASON opening roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

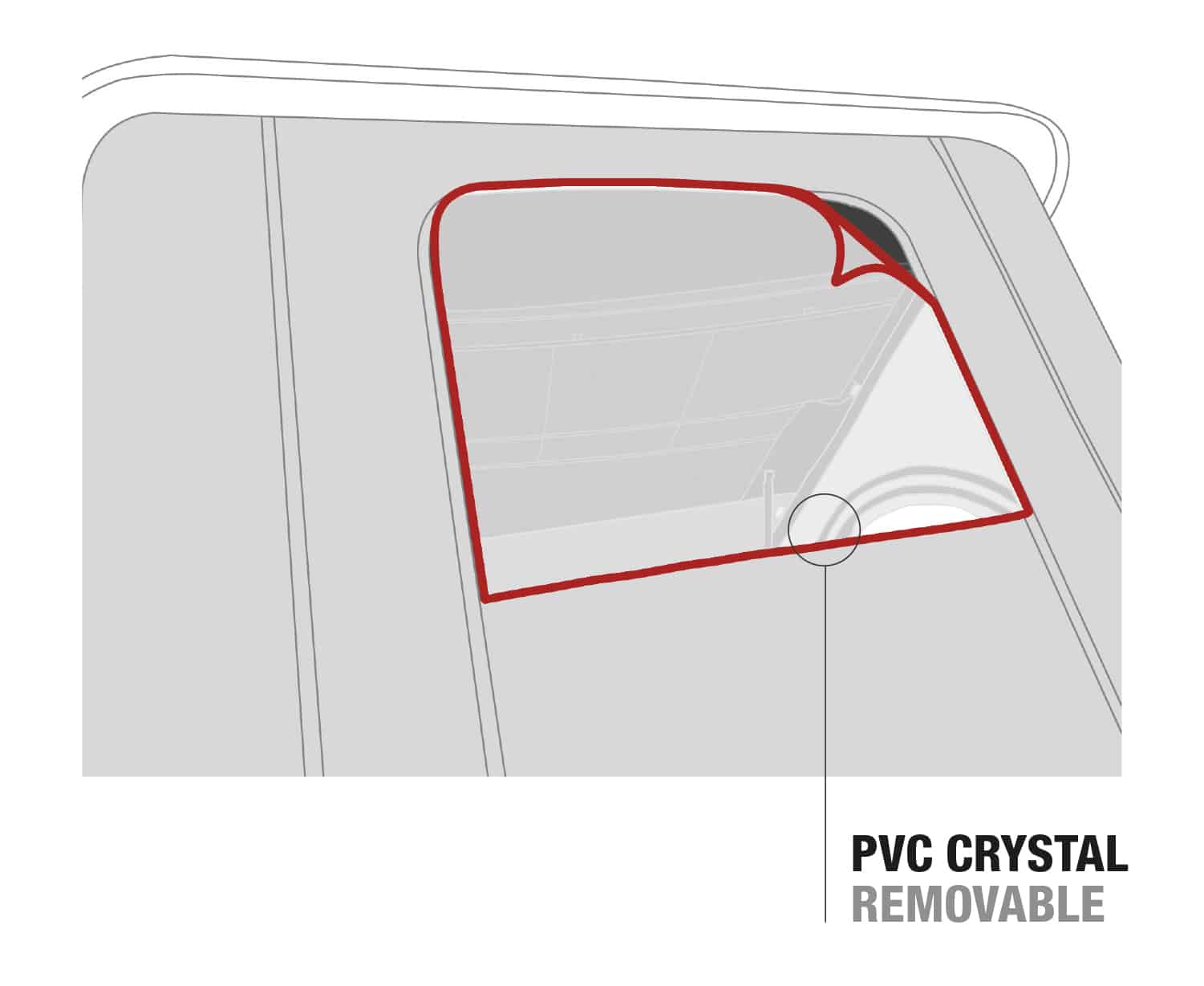

✓ The useful protective pre-entry, ideal in case of bad weather, becomes standard. The transparent Crystal panels supplied with the tent, strictly removable, allow you to enjoy the view while it rains outside.

✓ The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric is used, in a toned down black colour for Overland and Olive Green for Overzone, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

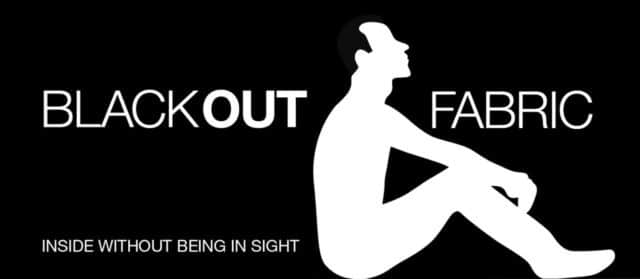

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

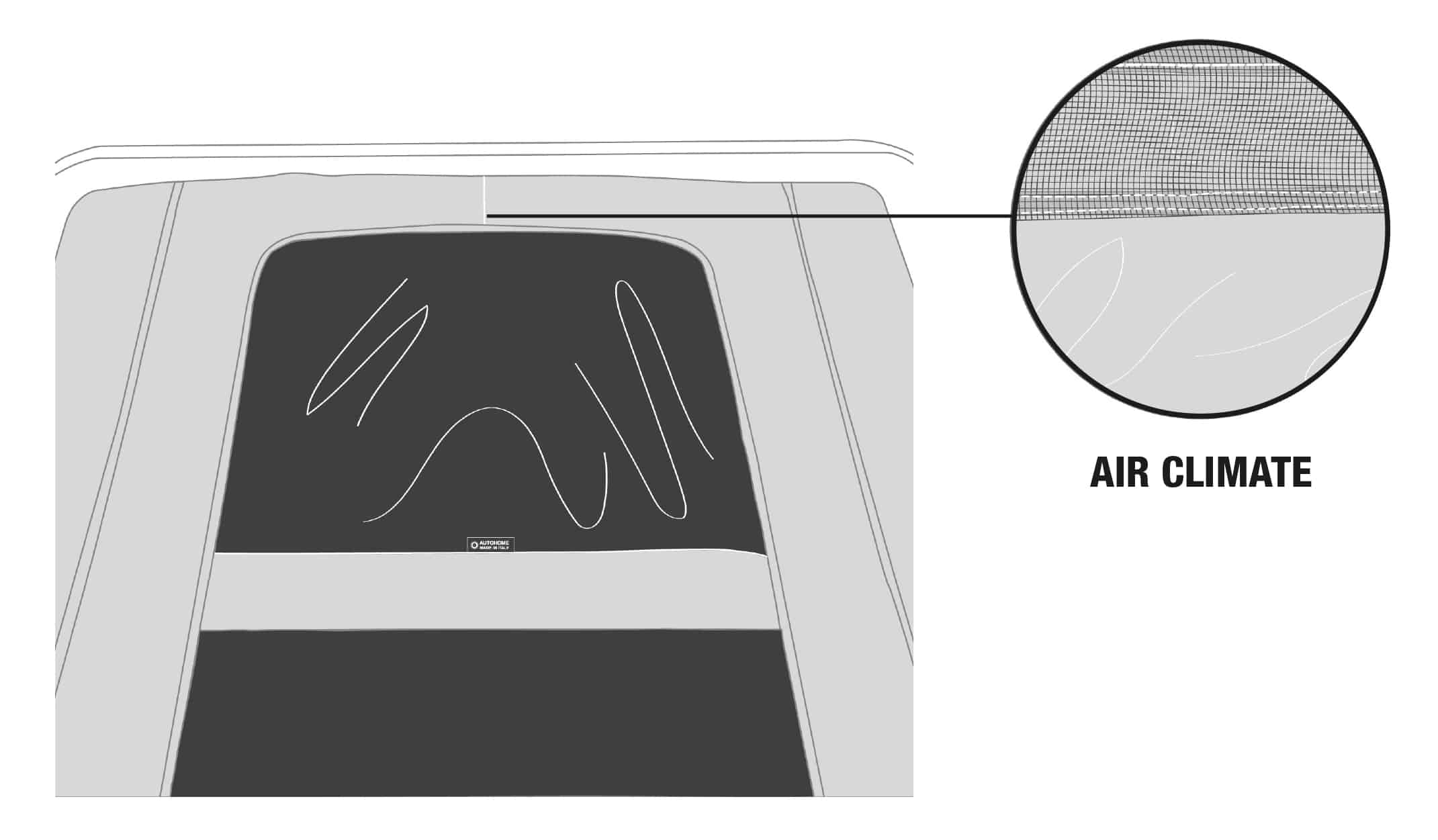

✓ Overland and Overzone are fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

✓ Technical reasons as lead to the selection of these colours. The double-sided black roof and the Carbon colour on the walls do not filter the first lights of the day.

✓ A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

✓ It is the fundamental element to sleep well.

To decide what to offer, Autohome specialists tested different solutions and carried out different tests. The market offers multiple proposals: coupled sponge rubbers, shaping rubbers, layered rubbers, shaped rubbers, massage solutions and even extravagant. But Autohome choosed only the best, to satisfy even the most demanding customer.

✓ All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

✓ Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

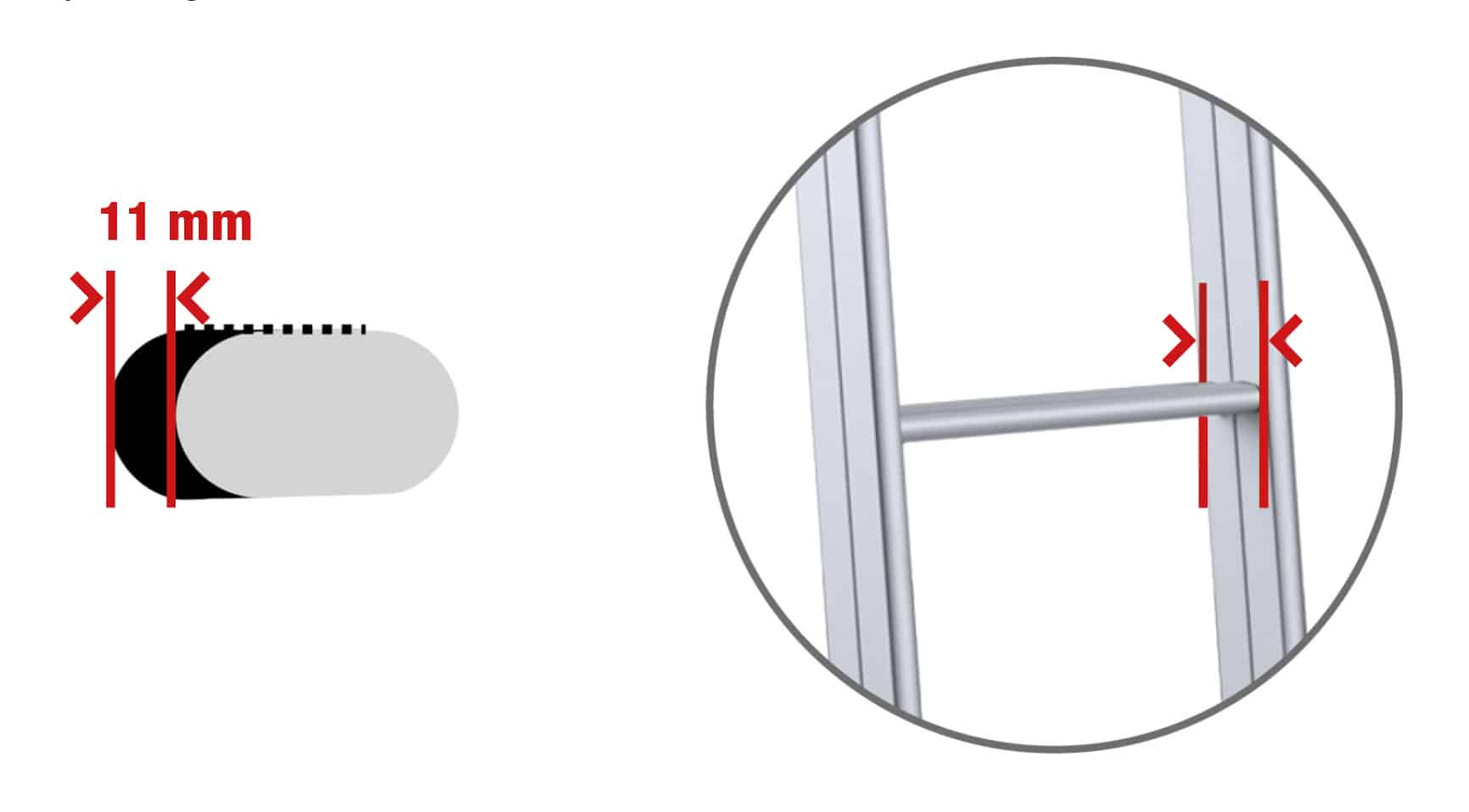

✓ The ladder was redesigned to achieve the best goals of functionality, reliability, and comfort.

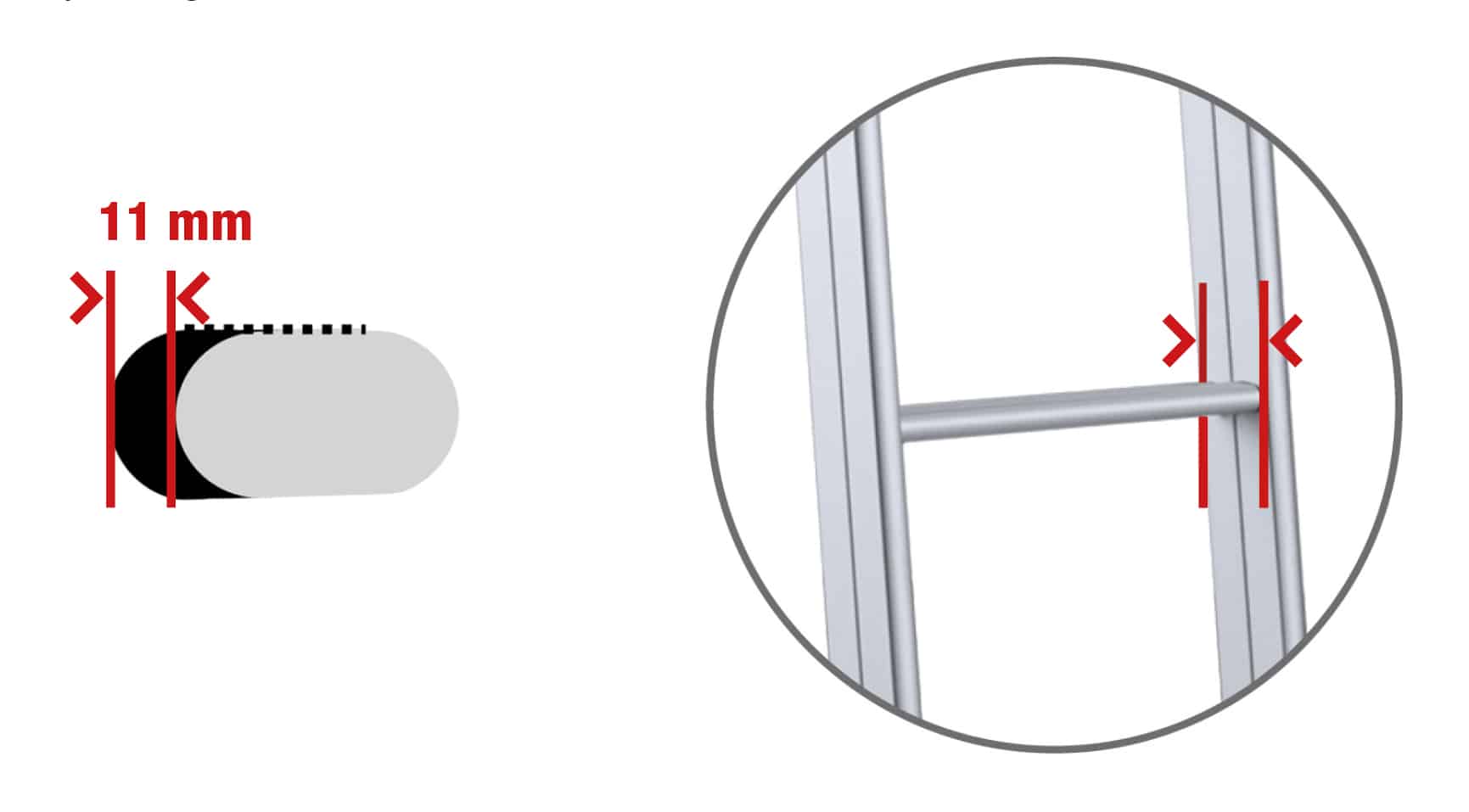

First, it is made of stainless steel (a material, a certainty!), with wide wooden steps. Especially designed with minimum thickness uprights, it remains housed above the closed tent without deforming the cover. Designed and manufactured specifically for the Autohome tents. Nothing comparable to the low-cost roof tents not specific to this field of application.

– The ladder is an integral part of the frame, this is directly connected to the backbone of the tent (i.e. to the hinging of the two halves of the planes) by 2 omega support profiles placed diagonally, so as to better distribute the weight of the occupants. The result is: less flexions, more resistance, more stability and reduced thickness to a minimum.

A patent born in Autohome that since 1958 many tried to imitate, without success. Its uniqueness is the result of several interrelated factors:

– It is always ready and easily deployed.

– It is designed with a ladder block, to avoid slipping on slippery ground or floors.

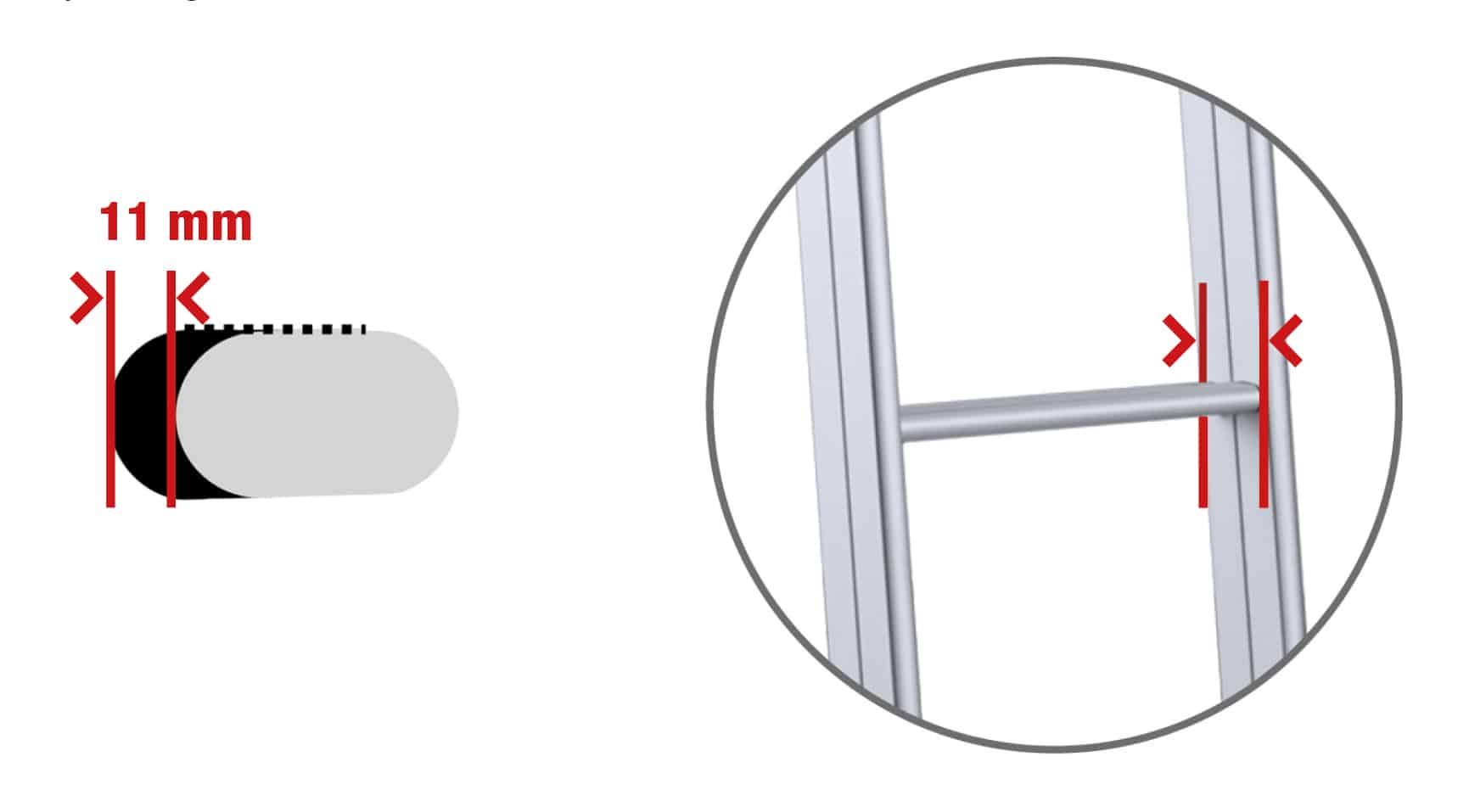

– EASY USE telescopic adjustment is a very reliable smart solution, that has made the history of the roof tent. It is easy to adjust and is always functional.

– The ladder can be quickly extended to fit any height, within its maximum length of 2.30 m

– Compact and linear, it does not generate protrusions or malformations to the cover when the tent is closed while travelling.

– It is fitted with sturdy wooden steps, waterproof and water-repellent. Elegant, natural and of pleasant design, they offer a wide non-slip support. They also do not warm up in the sun and thus always allow you to climb barefoot.

Our Cover is even more sturdy.

A solidity which is the result of specific choices, starting from the materials: 600Gr/sqm PVC with 900gr/sqm reinforcements in the most stressed points. A solidity enhanced by a special shaping with internal seams, more resistant than normal welding. More precisely, they do not fall apart. A synergy to withstand even the highest climatic temperatures and offer superior aerodynamic stability.

With a regular parallelepiped shape, our covers have slightly rounded corners to enhance stability and safety, so they do not require upper ties with visible straps, affecting the tent aesthetics of the tent. The result is a clean and tidy line, to always travel with style.

Drawing on the experience of the most performing commercial vehicles, such as big lorries and curtain-sided trucks, Autohome covers also use a perimetral adjustable elastic rope for binding, in order to compensate for any expansion of the materials due to weather conditions: the cover remains well-fitted to the tent, without any zipper.

A choice of reliability made in 1958 and always confirmed, considering also that the elastic rope is easy to replace. 6mm in diameter and variable length according to the perimeter or model of the tent. The coupling and the regulation are carried out by two carabiners placed at the ends. Today the coupling and uncoupling is easier even when the tent is fixed on the roof bars or on baggage racks, thanks to the special tool supplied together with the cover.

This practicality is appreciated in every condition: you will have no problem in case of unfastening or coupling even in the desert, in marshy areas, on muddy roads, in the presence of foliage and shrubs, because the elastic tie rod always works and will never fail.

The quality of our cover is branded with the Autohome logo on the 110 cm short side, while on the long side there is a label representing the legendary paths of Nino Cirani. Black was chosen for the colour: always elegant and anti-stain.

✓ Overland and Overzone are available today with an ALL-SEASON opening roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

✓ The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric is used, in a toned down black colour for Overland and Olive Green for Overzone, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

✓ Overland and Overzone are fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

✓ Technical reasons as lead to the selection of these colours. The double-sided black roof and the Olive colour on the walls do not filter the first lights of the day.

✓ A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

✓ All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

✓ Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

✓ It is the fundamental element to sleep well.

To decide what to offer, Autohome specialists tested different solutions and carried out different tests. The market offers multiple proposals: coupled sponge rubbers, shaping rubbers, layered rubbers, shaped rubbers, massage solutions and even extravagant. But Autohome choosed only the best, to satisfy even the most demanding customer.

✓ The ladder was redesigned to achieve the best goals of functionality, reliability, and comfort.

First, it is made of stainless steel (a material, a certainty!), with wide wooden steps. Especially designed with minimum thickness uprights, it always remains housed above the closed tent without deforming the cover. Designed and manufactured specifically for the Autohome tents. Nothing comparable to the low-cost roof tents not specific to this field of application.

– The ladder is an integral part of the frame, this is directly connected to the backbone of the tent (i.e. to the hinging of the two halves of the planes) by 2 omega support profiles placed diagonally, so as to better distribute the weight of the occupants. The result is: less flexions, more resistance, more stability and reduced thickness to a minimum.

A patent born in Autohome that since 1958 many tried to imitate, without success. Its uniqueness is the result of several interrelated factors:

– It is always ready and easily deployed.

– It is designed with a ladder block, to avoid slipping on slippery ground or floors.

– EASY USE telescopic adjustment is a very reliable smart solution, that has made the history of the roof tent. It is easy to adjust and is always functional.

– The ladder can be quickly extended to fit any height, within its maximum length of 2.30 m

– Compact and linear, it does not generate protrusions or malformations to the cover when the tent is closed while travelling.

– It is fitted with sturdy wooden steps, waterproof and water-repellent. Elegant, natural and of pleasant design, they offer a wide non-slip support. They also do not warm up in the sun and thus always allow you to climb barefoot.

Our Cover is even more sturdy.

A solidity which is the result of specific choices, starting from the materials: 600Gr/sqm PVC with 900gr/sqm reinforcements in the most stressed points. A solidity enhanced by a special shaping with internal seams, more resistant than normal welding. More precisely, they do not fall apart. A synergy to withstand even the highest climatic temperatures and offer superior aerodynamic stability.

With a regular parallelepiped shape, our covers have slightly rounded corners to enhance stability and safety, so they do not require upper ties with visible straps, affecting the tent aesthetics of the tent. The result is a clean and tidy line, to always travel with style.

Drawing on the experience of the most performing commercial vehicles, such as big lorries and curtain-sided trucks, Autohome covers also use a perimetral adjustable elastic rope for binding, in order to compensate for any expansion of the materials due to weather conditions: the cover remains well-fitted to the tent, without any zipper.

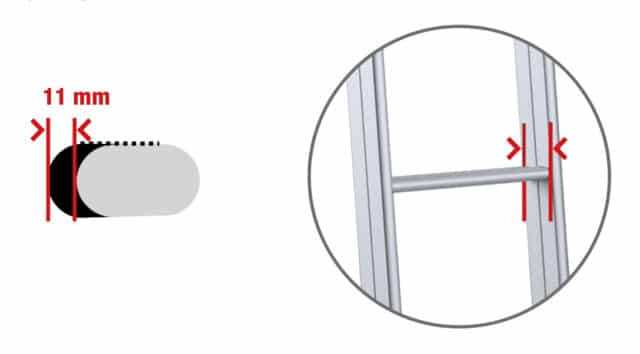

A choice of reliability made in 1958 and always confirmed, considering also that the elastic rope is easy to replace. 6mm in diameter and variable length according to the perimeter or model of the tent. The coupling and the regulation are carried out by two carabiners placed at the ends. Today the coupling and uncoupling is easier even when the tent is fixed on the roof bars or on baggage racks, thanks to the special tool supplied together with the cover.

This practicality is appreciated in every condition: you will have no problem in case of unfastening or coupling even in the desert, in marshy areas, on muddy roads, in the presence of foliage and shrubs, because the elastic tie rod always works and will never fail.

The quality of our cover is branded with the Autohome logo on the 110 cm short side, while on the long side there is a label representing the legendary paths of Nino Cirani. Black was chosen for the colour: always elegant and anti-stain.

✓ Large window designed to offer an excellent view, but above all great privacy. When open, it assures the right privacy and cosiness.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ The size of the shells is confirmed, so their capacities are unchanged. While in the Large models they are reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

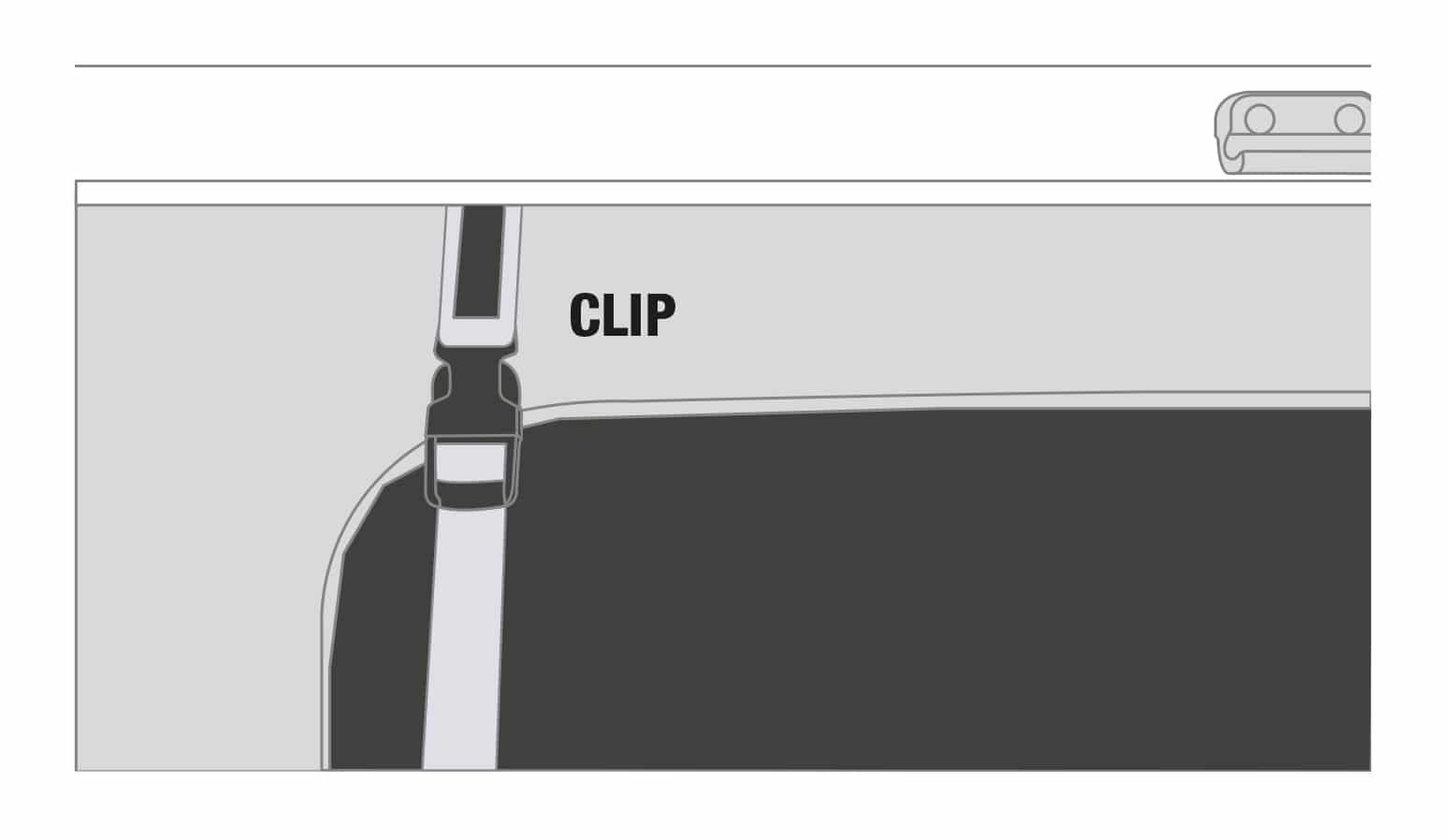

✓ Comfortable and adjustable element, firmly attached to the shell, it allows to lower the roof and facilitates the closing phase. Now it is also easily removable. An evolution which avoids noise in case of wind and reduces the overall dimensions. The roll clips of the back door can be locked by Velcro directly under the drip of the roof. The whole system is windproof.

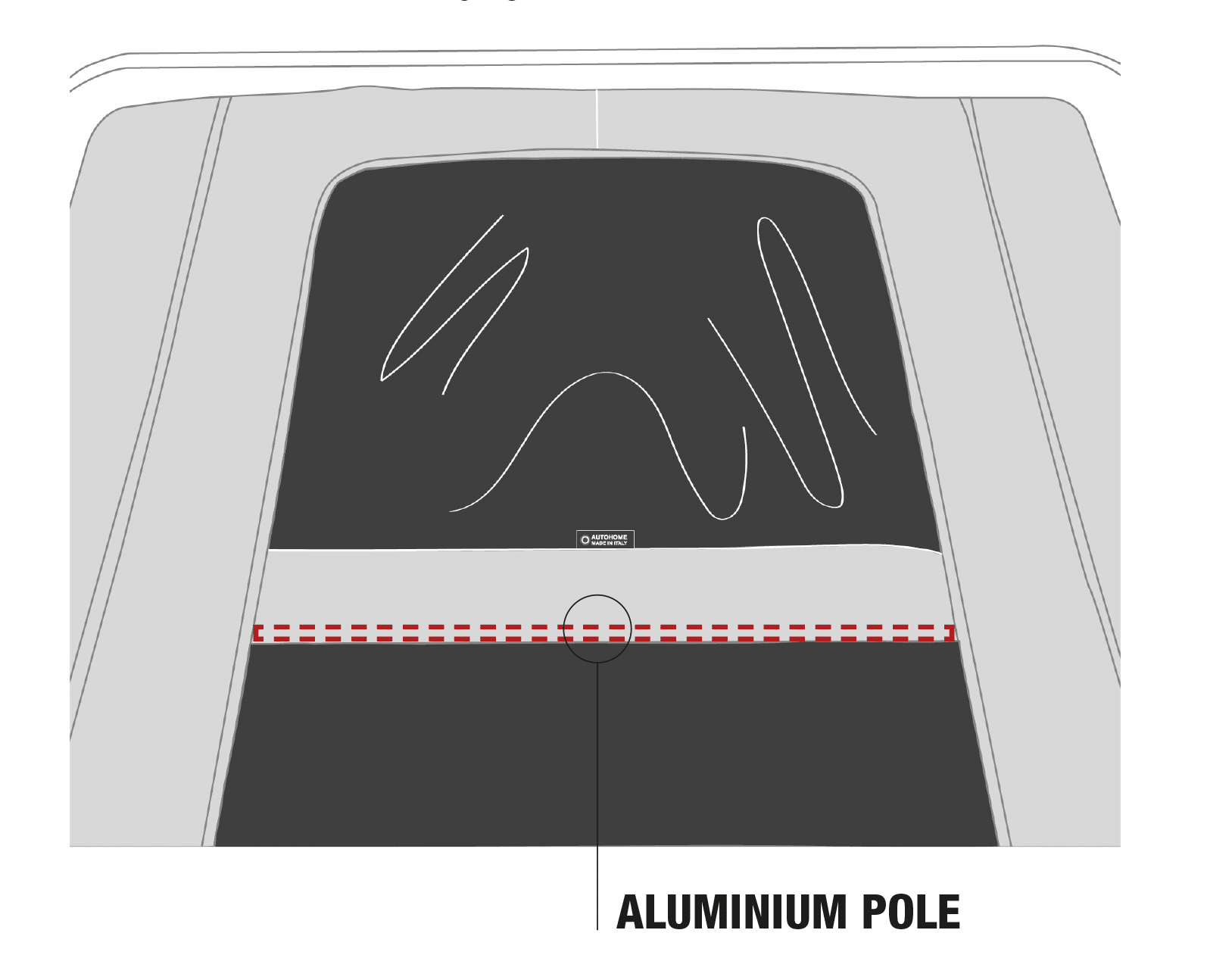

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved; the NATURE WHITE and BLACK STORM colours are confirmed.

It should be noted that the DOMESTIC WHITE colour of the basic models is running low.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ Colours of the AUTOHOME logo on the shells have been renewed: silver, black variant on demand on Black Storm models.

✓ The additional perimeter protection, ideal in bad weather, becomes from today a “standard” solution.

Wing means two prominent eaves on the side entrances, and a wide back protection. This self-supporting solution can be easily attached to the roof with Velcro and a modular arched pole.

The feeling of protected space and airiness is remarkable: an upgrade designed to increase attention and appreciation.

✓ Entirely redesigned, it offers even more functional and customizable solutions. The transparent glass PVC needs to be mentioned, allowing to see outside even in case of bad weather, which now become removable. The customised back door openings are supported by aluminium poles embedded in the fabrics, to counteract the negative effects of the wind.

✓ Comfortable and adjustable element, firmly attached to the shell, it allows to lower the roof and facilitates the closing phase. Now it is also easily removable. An evolution which avoids noise in case of wind and reduces the overall dimensions. The roll clips of the back door can be locked by Velcro directly under the drip of the roof. The whole system is windproof.

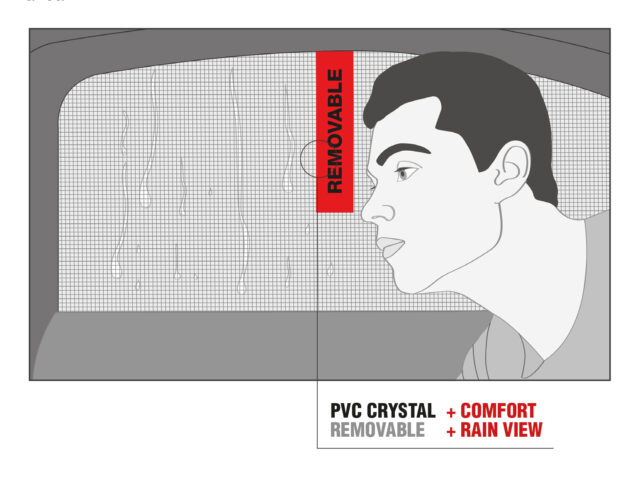

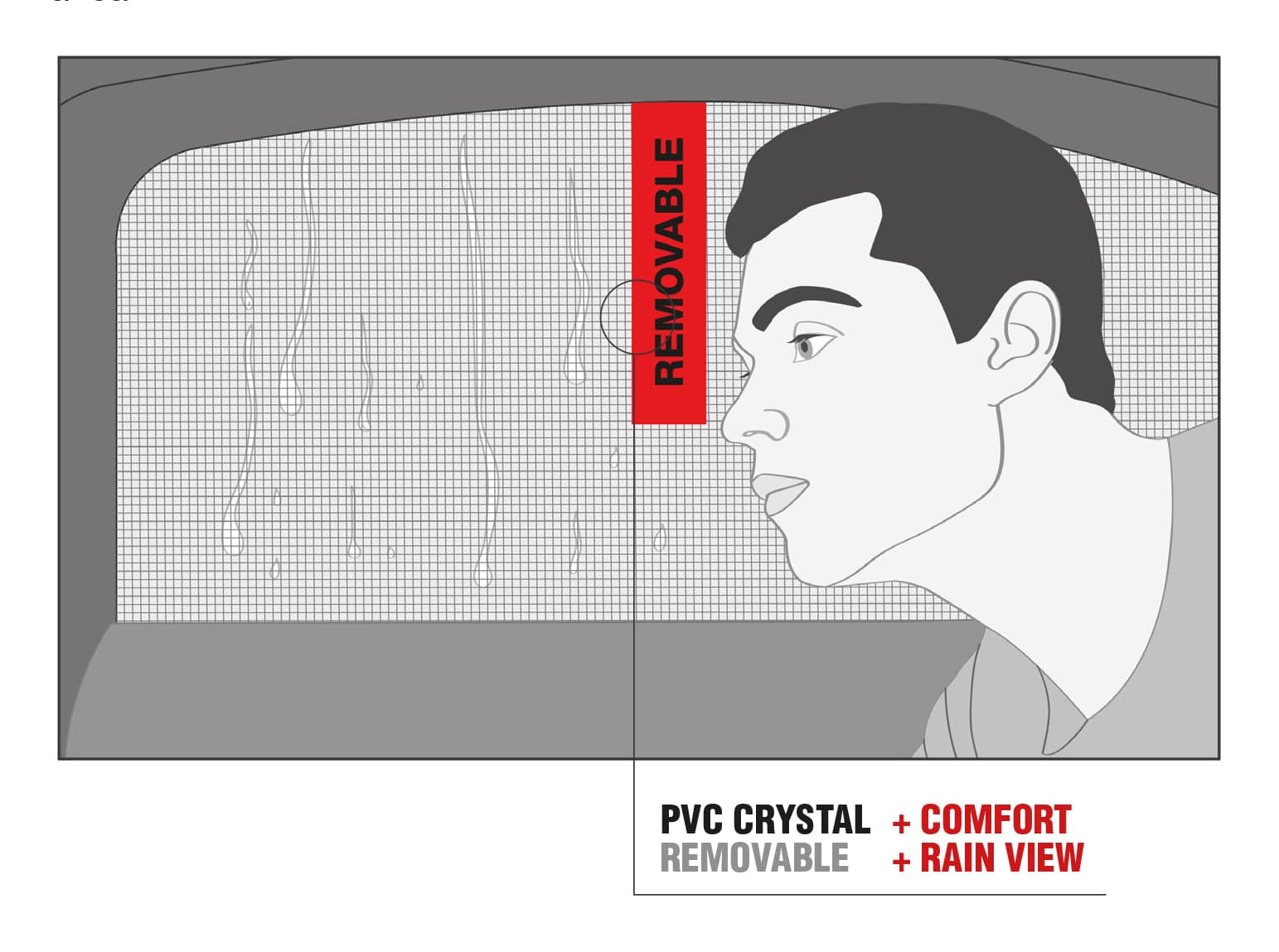

✓ A transparent PVC window allowing to see outside even in case of bad weather, always fixed and permanent, is now removable when needed. PVC can be a source of heat retention and condensation, so the fact that the window can be removed is very useful when environmental conditions lead to a high rate of humidity and heat, for example during the sultry summer nights, when the feeling of discomfort is accentuated by body evaporation.

The window, fitted in the upper part of the rear door, can be easily applied and removed thanks to the special Velcro.

✓ The internal ventilation system, which is now called AIR CLIMATE, changes its appearance and size. It now has a wide opening in the upper part of the fabric, 80 cm wide, which efficiently and naturally promotes air exchange.

✓ A new solution applied to the inner ceiling, equipped with closeable pockets to prevent objects and other materials falling.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ The size of the shells is confirmed, so their capacities are unchanged. While in the Large and X-LARGE models they are reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved; the NATURE WHITE and BLACK STORM colours are confirmed.

It should be noted that the DOMESTIC WHITE colour of the basic models is running low.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ Colours of the AUTOHOME logo on the shells have been renewed: silver, black variant on demand on Black Storm models.

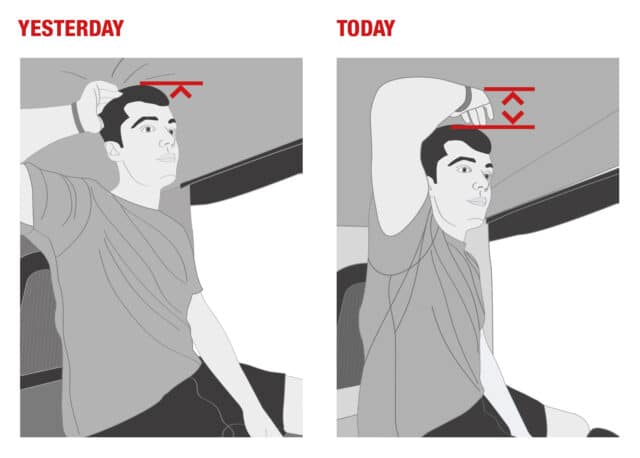

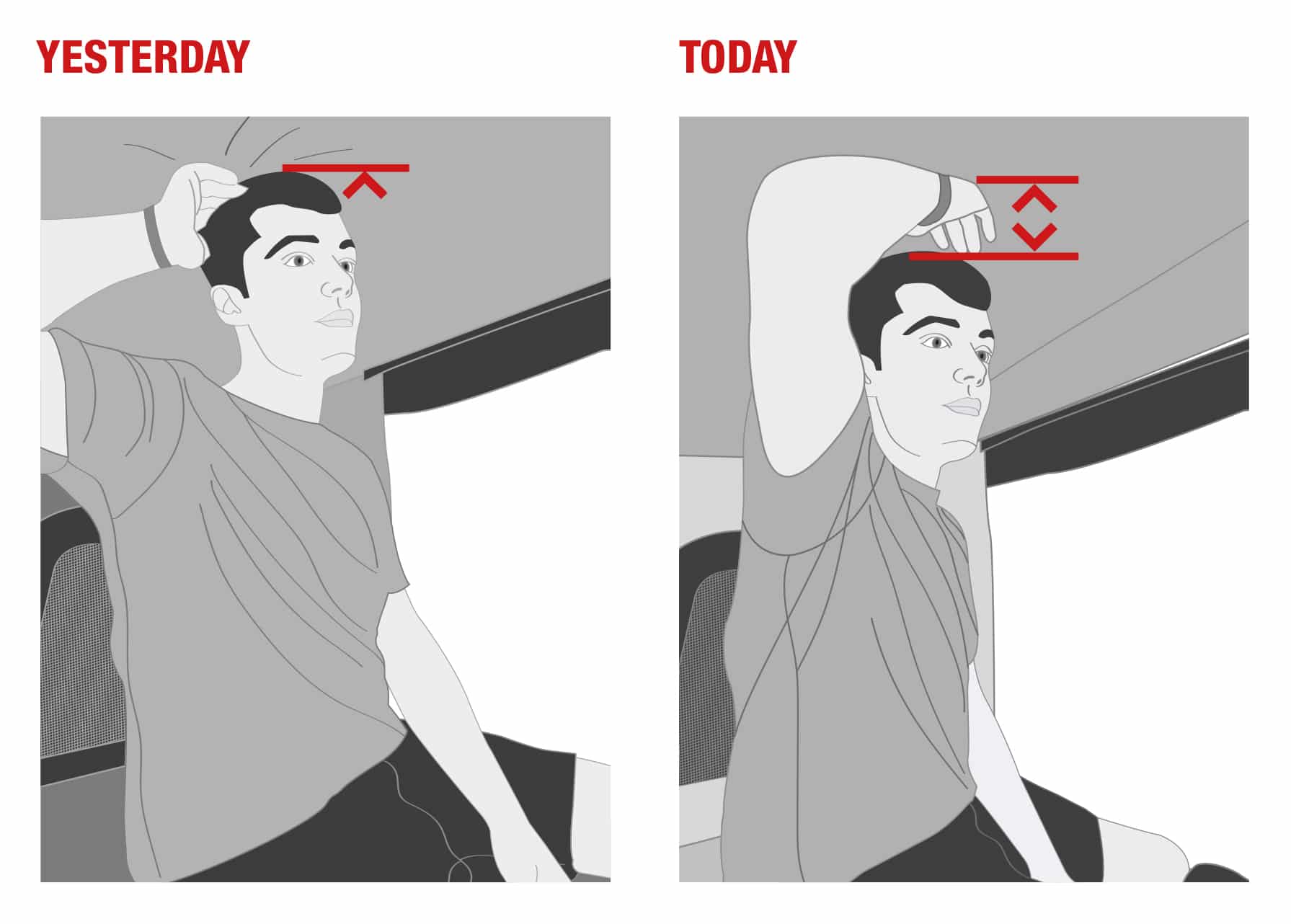

✓ All Maggiolina and Airtop tent models, when opened, now have a higher height. An important upgrade, which does not change the natural stability that is an integral part of the success of these tents.

✓ Increasing the internal height, the comfort of the product changes significantly: the raised roof of the new series, allows you to stay agile, having easy motions even while sitting in the tent. The feeling of space and airiness is really unique.

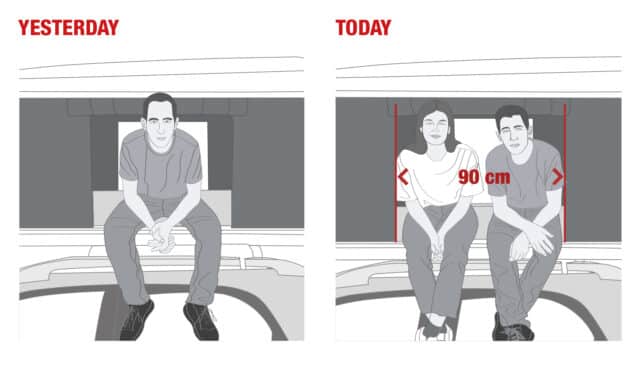

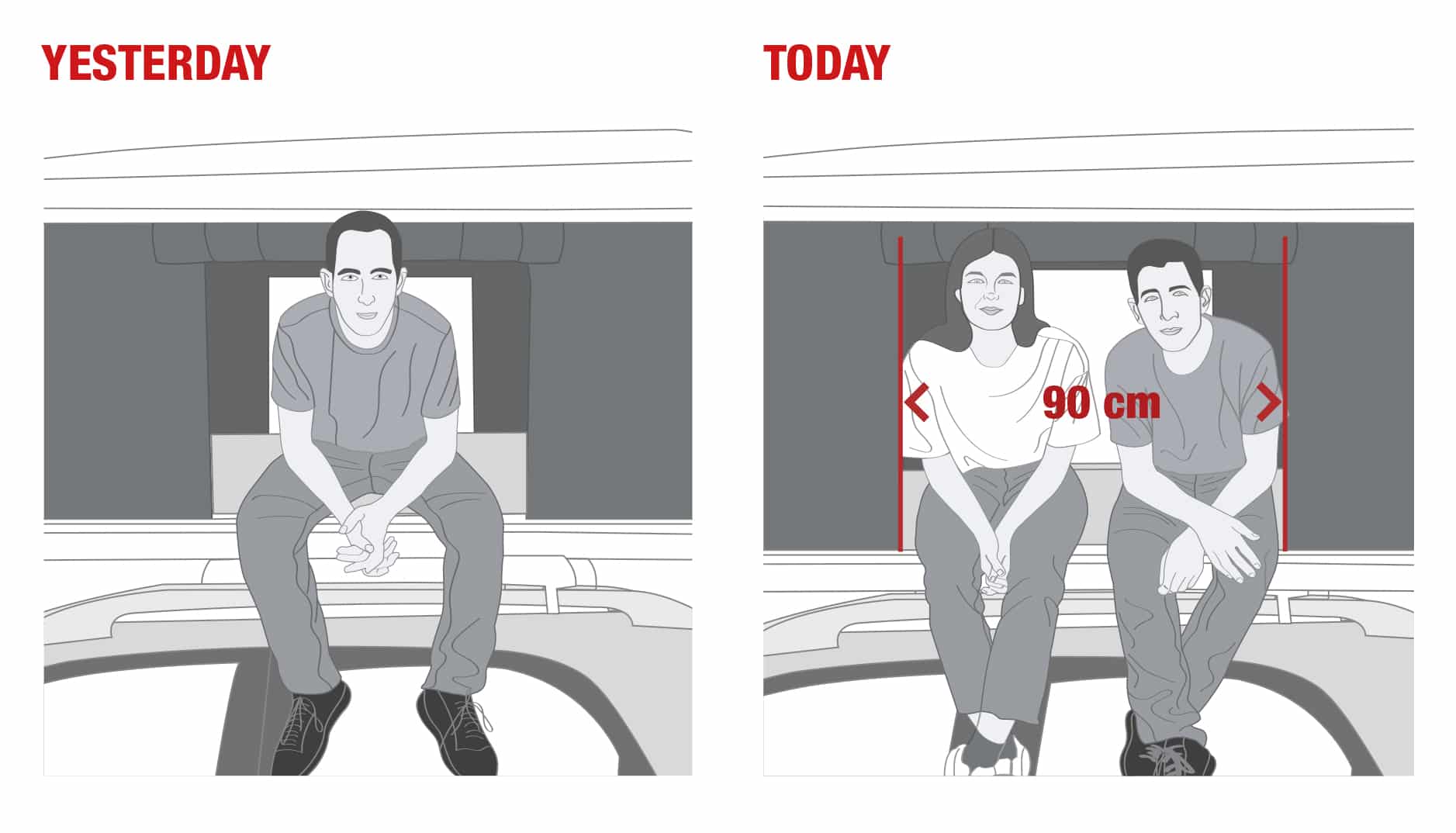

✓ The doors are even larger; 90 cm. The tent becomes even more welcoming and functional, as well as offering the advantage of facilitating the moments of dressing and undressing. It should also be noted that these wide openings are easily transformed into large windows with a custom opening.

✓ A further opportunity: the 360 tent models are fitted with transparent PVC glass protections to see outside even in case of bad weather. Both on the right and left side of the tent you have a great view. Of course, the Crystal protections are removable in case of intense humidity and heat. This new feature makes the 360 models even more pleasant to live in all weather conditions.

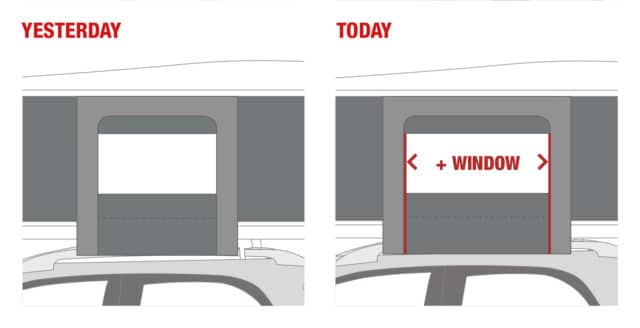

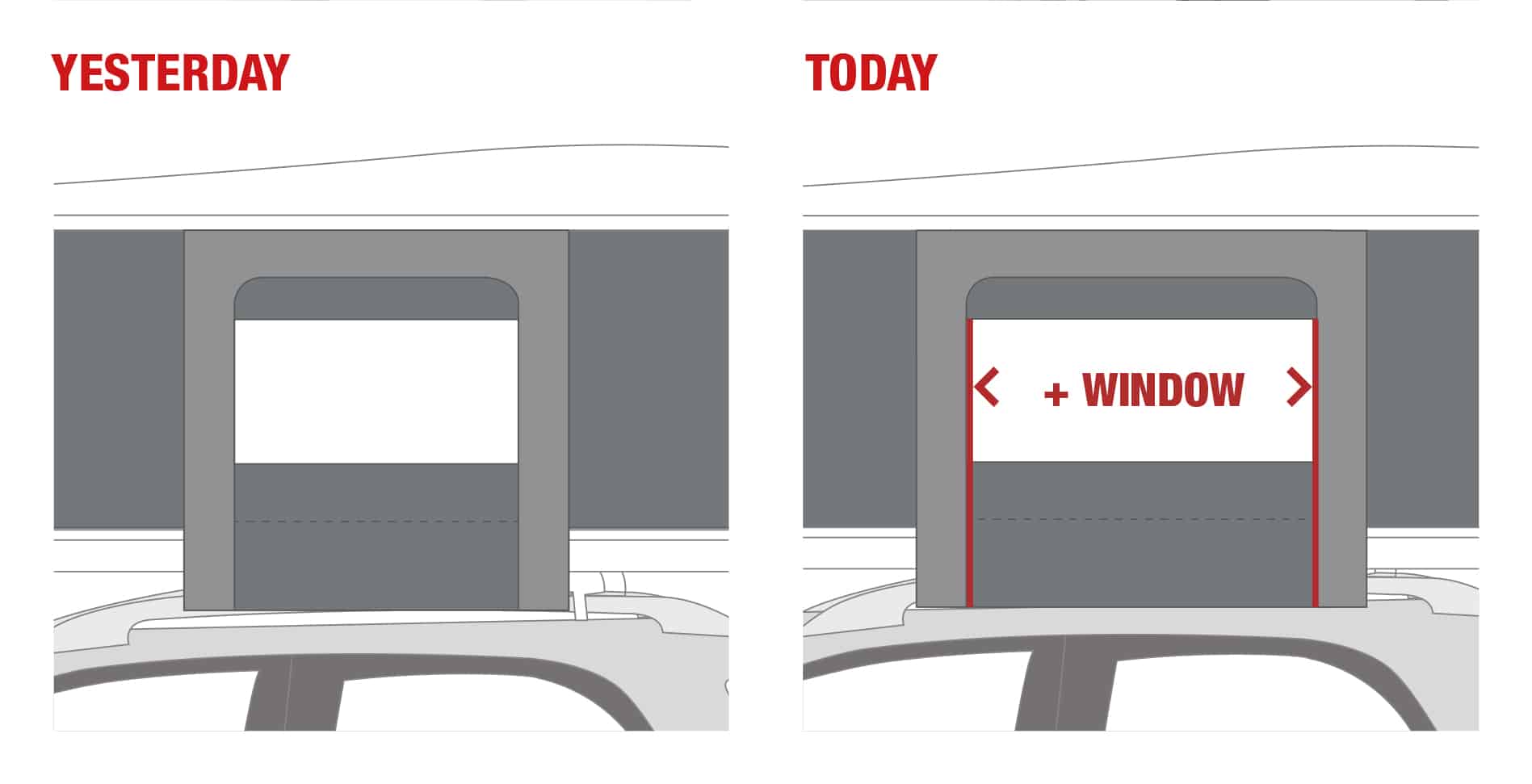

✓ The principle of greater livability (+ livability + airiness) also characterizes the windows, thanks to larger dimensions, without affecting privacy.

✓ The 360 models are fitted with a removable transparent Crystal protection. These windows are not permanent on the tent, they can be sources of heat and condensation, even when simply rolled up. That is why they are fitted with Velcro that makes them easily and totally removable when necessary. The tents are provided with a flat bag for the windows which can be stored under the mattress.

✓ A new solution applied to the inner ceiling, equipped with closeable pockets to prevent objects and other materials falling.

✓ Better waterproof capacity, while the breathability remains almost unchanged, as it is an essential characteristic for Autohome.

✓ Firmly made in Fiberglass, they have been further reinforced: a manual pressure is enough to highlight the quality and robustness achieved in the new series, especially the roof.

Glass Reinforced Plastic is therefore an anti-UV material with undisputed and well-known advantages: stability, acoustics, thermal insulation, lightness, repairability in case of accidents or breakages, non-deformability, and durability.

Like those of the best fiberglass boats, flawless and always in shape, they are not subject to degradation.

✓ They are an integrated part to the design of the upper shell and today their section is slightly increased. When the tent is closed, while travelling, it gives more protection and better counteracts the impact of the air coming from each direction. When the tent is open, it reduces the flow of rainwater on the fabrics offering a greater protection. A significant detail, whose efficiency is highlighted over time.

✓ Based on their excellent functionality, the size of the shells and their capacities are confirmed. While for the Large and X-LARGE models the shells have been reinforced to increase their stability.

✓ Located under the roof, it increases its section with a durable effect against infiltration of water, dust and sand while travelling.

An even more airtight and elastic closure is ideal to withstand the most demanding Off Road stresses.

✓ The section of the step was enlarged for a more comfortable support of the foot and to have a more agile and easy climb. On the other hand, the discharges on the ladder joining plates are confirmed. To block the ladder, there is the Lock Security system, which is provided as standard.

✓ The fixing points of the aluminium profile of the base were doubled in mechanical form, thus the structural rigidity is much improved and even more robust people can you the tent safely.

✓ The gap was increased in thickness, as well as the anti-condensation layer. Result: a more isolated roof, less noisy in the rain, softer and pleasant to the touch.

✓ The quality of the GELCOAT has been improved. The NATURE WHITE and BLACK STORM colours have been confirmed.

The Extreme Series is confirmed only in the Black Storm version.

✓ The forces of the springs have been increased to have a more tensioned fabric. In addition, the closure is easier, thanks to the new arrangement of the levers and springs.

✓ The new device is adopted, which blocks the glass of the upper window when it is completely open at 90°.

✓ A special protection is now available, valuable in the event of incorrect closing manoeuvres by the user.

✓ Colours of the AUTOHOME logo on the shells have been reviewed: bronze on the models with a crank opening, silver for the models with gas springs opening. Black variant on demand on Black Storm models.

Overcamp is available today with an ALL-SEASON roof, multifunctional and completely renewed, to sleep truly outdoors, protected and in total privacy.

The useful protective pre-entry, ideal in case of bad weather, becomes standard. The transparent Crystal panels supplied with the tent, strictly removable, allow you to enjoy the view while it rains outside.

The fabric of the roof is polyester 255 g/m2 coupled with an anti UV blackout net of 170 gr/m2, which reaches a waterproofness equal to 1000 mm of water column.

For the sides, on the other hand, a combined 50% cotton and 50% polyester fabric, in GRAY colour, to guarantee a high breathability of 53 mm/s in addition to waterproofing. Its consistency is 420 g/m2 to offer excellent stability.

In addition, the fabrics used are Blackout: they do not let the light filter, neither seeing the shapes of the occupants.

One more advantage: The combination of the two fabrics provides for a breathable anti-condensation cabin.

Overcamp is fitted with new high-tech darkening mosquito nets.

From the inside it is possible to see outside, but from the outside it is not possible to see inside.

Technical reasons as lead to the selection of these colours. The double-sided black roof and the grey colour on the walls do not filter the first lights of the day.

A widely tested, high-tech yarn, composed of two different fibres is used.

Cotton on the outside to inflate and fill the holes produced by the needle, and on the inside a synthetic core to obtain a considerably higher resistance than cotton.

All metal parts are designed and produced exclusively by Autohome.

After a careful evaluation of the advantages offered by the lower weight of aluminium alloys, it has now been decided to prefer steel. Although we wanted to maintain the ladder and aluminium elements as in the past, the total weight of the tent could be reduced by no more than 4-5 kg. So, we chose a stable, durable, and long-lasting bed.

Poplar plywood is used because the material, with its long fibre, is also more elastic and resistant. It is made specifically for the specific Autohome production in 7 layers. These are glued together in cross-overlay, according to the grain of the plant to improve the characteristics of the product. Subsequently the platform is finished with two sheets of black plastic for both the interior and the exterior. Thus, the plywood is totally waterproof and water-repellent both on the outside and inside. Consequently, by not absorbing moisture, it does not deform and favour the formation of mould. An excellent result, not comparable to normal polyurethane foam floors, alveolar structures, synthetic or lightened with polystyrene, all of precarious resistance and poor durability over time. The Autohome platforms do not mark, deform, crack or crumble.

The SMALL (2 Places in Measurements 130 cm x 200) and LARGE (4 Places in Measurements 180 cm x 200) sizes are confirmed.

The section of the step was enlarged for a more comfortable support of the foot.

MORE NEWS AND DETAIL

How many kilometres of road and how many years of history lie between Dallas in Texas and Rivarolo Mantovano, an ancient medieval town dominated by the Gonzaga family? A lot. And maybe just the idea of a journey, of sharing special experiences could lead me to choose to leave the US to move here. A decision that says a lot about what Autohome means to me, the mythical roof tents for big travellers, like Nino Cirani for example. In Texas we may not know Rivarolo Mantovano, but we know well what Autohome quality means: travelling quietly all over the world. Masterpiece tents, like the works of art that made Italy great. Like the creations of the most famous fashion designers.

Since I have been here in Italy, I have noticed that Italians are all a bit artists, and in Mantua even more: the taste of beauty is in their hearts, they carry it inside them, if only to judge by the monumental and architectural beauties that characterize their territory.

Today I am 37 years old and have been working in Autohome since 2002. 19 years of working life in the midst of roof tents. So, I think I know these products very well, which allow you to have a rewarding holiday in complete freedom: you stop where you want, especially with the shell tents that remain more shaped to the car. The fabric tents are obviously not bad, also very habitable. But a little more binding when you have to make scope at least in different European nations. It is better to go camping or in equipped areas. At Autohome we are a big and beautiful family, all enthusiastic about the products we manufacture. If I have to say the product that I prefer for me is Maggiolina Extreme Forest. I really appreciate the colour green, perhaps also because I have always been looking for it. Texas is largely desert, while my soul is in the great forests… All to be covered with an Autohome tent on the roof.

I introduce myself: I am Alessandro Spiridonica and in Autohome I am liable for the warehouse. I joined the company three years ago and I became manager, a result that naturally gives me great pleasure and many satisfactions. Although I am aware of the great responsibility that this role entails.

It is in fact a job that if on one hand I like a lot, on the other hand it requires an extraordinary effort, especially at some times of the year… For example, in the months of June and July I would rather be… somewhere else in the world, travelling with my Overzone, my favourite tent. I appreciate the military green colour. It is, among other things, a particular green, at the same time delicate and with a strong personality. Combined with the safari-coloured roof, it makes the tent a pass-partout for any destination and adventure: congratulations to the colleagues of the style office! In addition, the fabric is particularly consistent, because it responds to precise military specifications, another element that gives solidity to the tent. A safety that does not give up comfort and well-being: the degree of breathability is in fact high, equal to 53 mm/s, in line with ISO 9237-97 standards. I do not want to be too “technical”, but they are decisive when choosing a tent. These are the factors that lead me to say: do not be “dazzled” by the mirages of low-cost products that seem of quality, but then result in low breathability. During travel they can become your worst nightmare!

Remember instead that Overzone is a real roof top tent, with a roof that is integral to the walls. It is 100% original Autohome and Made in Italy. That is all I have to say.

To make great roof tents you need the right ingredients and a lot of dedication, just like for high quality cooking. I did not make this reference by chance: before joining the Autohome staff I worked in high-level catering, an area where I won many awards and recognitions. What made me change my field of interest? The immeasurable passion for travel and for the product that best interprets this desire: the Autohome tents.

As you can see, my professional commitment did not change: my job, in fact, today as yesterday, is to carry out a final check before “serving the dish” or sending the tent to the customer.

I am also passionate about vintage motorcycles and vehicles: originality and history always appeal to me. I find a perfect synthesis of this double passion of mine in the epic of Nino Cirani and his faithful Overland tent.

It is precisely this tent that I will install this year on my vintage “Ape Car”, purchased to move in an unconventional and completely new way. The intention is to make a few tours in Southern Italy, I am sure that with my vehicle equipped with Overland I will not go unnoticed! And this will be my contribution, out of the box but original, to proudly declare to everyone that I am part of the great Autohome family!

Working with fibreglass I think is “an art”. A sort of alchemy, when human and technical skills are perfectly matched. It is a demanding job, which requires knowledge in different disciplines: physics, chemistry, mechanics… Supplemented by a lot of manual wisdom and patience as well.

Being in charge of one of the company departments that deals with “shells” (the first in order of time… we were real pioneers in our sector!) is always exciting, even if now there are many of us in the team. I am one of the oldest employees of the company, I started in 1985 and today I am proud to teach the job to young people willing to. I manage about 20 great people. Our activity is mainly related to shell painting. In other words, this is the first operation followed by the laying of the glass fibre using rollers and brushes, an almost entirely manual operation.

As I said, dexterity is matched with technology. I also mentioned patience, because the times for moulding a fibreglass product are very long. However, this attention plays a significant role in defining the superior quality of Autohome. Because our shells are not made of molded or thermoformed plastic, typical of certain serial productions made in Asia, where even more than 20 pieces per hour are mechanically manufactured… too many, but not very good quality as well!

While in Autohome, making a shell takes almost a lifetime, but it is the right way to get a more stable and durable tent. In short, fiberglass has always been the Top for 60 years, as we try to explain in our info. I smile when they tell us: “you in Autohome are geniuses, Italian geniuses…” While I simply think that we are a great family, certainly Italian, who loves things done well.

If you think that dealing with fabrics in Autohome means taking care of only one type of material, it is better… that I explain who I am and what I do! I am liable for coordinating the entire fabric department. I am “the Trainer” of a great team, attentive and meticulous. Our job is to draw and cut fabrics, in particular by managing laser cutting machines. I constantly co-operate with the other production and packaging departments. Ours is a very demanding activity, sometimes really stressful, especially because we have to keep a pace to allow the entire production chain to proceed efficiently, without interruptions.

In addition to this task, I am also liable for the quality control of the raw material, I cannot afford mistakes or put into production a fabric that is not perfect. My company is very demanding and so am I.

We have different types of fabrics based on the model of the tent, a range that is based on multiple technical reasons, which would be long now to explain, but which I summarize as follows: quality.

And Autohome always aims to guarantee this goal: for each model a single fabric, at the top for quality. While those who standardize the raw material obviously reduce its production cost at the expense of quality. As you can imagine, many tents that come to the market, from Asia in particular, do not have fabrics suitable for the task they will have to do. While Autohome chooses only European-made fabrics, whose reliability is precisely defined and controlled. Also, for this reason Autohome means prestige. A fact of which I am truly proud of.

To the question “what is the best tent?”, I cannot give an answer, because anyone who knows this product well will tell you: it depends on many factors. Personally, I appreciate the shell models simply because I have a real roof over my head. Experts define these rooftops as “Active Hard Shell”. I think it is a perfect definition and it is worth more than many other words.

In my life I have always dealt with graphics. I love aesthetics, image, beauty in all its forms, whether it is a work of art or a design product. It may be due to fate, but I am now working in a company that knows these values well and applies them in its products.

I am therefore very happy to have been part of the Autohome team for a few years. I am originally from Mexico, whose national colours are exactly like the Italian ones: white, red, and green. Our flags say so much about our characters, which are also a bit similar: passionate like red and nature lovers like green. The white in the middle says: we choose according to our desire to prefer one or the other according to the mood of the moment! Perhaps it is because of these similarities between Mexico and Italy that I immediately found a total symbiosis with the country where the real roof tent was born, the product that Autohome made known and appreciated to travellers around the world.

I am very accurate, and I try very carefully to scrupulously follow every creative and image detail that is indicated to me by my marketing manager, Valentina. A young but very demanding woman, who rightly wants me everyday commitment and creativity, even in the smallest details.

I do not have a roof tent for now but being in Autohome is like… living with these tents every day! The product has all our attention and must be known well. On a general aesthetic level, I particularly love black. So even for tents I prefer the colour black, which is a real colour and knows how to excite! While for the tent model I like to focus on rationality, essentiality, that is why for me I would choose the Black Edition Overcamp.

Reading my name, you immediately understood that I am a person who recalls territories far from Europe, with the spirit of adventure in my blood. I was born in Persia. The rich Mesopotamia and the desert are my motherland, which I know well. Since I was little, I have been living in Germany, where I studied and grew up.

I personally manage the “Autohome DE” sales office. My clients are mostly Germans. In fact, I am liable for the commercial activity in Germany, and I support the Autohome central marketing office in the organization of our participation in the fairs that take place in Germany. My activity with headquarters is easy as I speak Italian.

Very often I also took part in research projects to develop new products, based on the experience I have gained both in the dealer field and with car manufacturers. For example, I was interested in the importance of mosquito nets for a roof tent, the selection of technical fabrics and the choice of some other materials that make up the tent. I believe, for example, that I reported to the Autohome staff how to obtain the best mosquito nets on the market: effective and at the same time rightly obscuring. I am constantly committed, with great passion, to providing advice to develop innovation on the products themselves, and this is thanks to the fact that I always interacted with a very demanding audience.

I am proud that my reports are taken seriously by Autohome Product Technical Management.

Although I am far from the company’s headquarters, I am always in contact with my Italian colleagues. My business can be said to have always been strongly linked to the outdoors. Already from my first job I worked in the sector, and I was an integral part of Bernd Woick for the management and sales and purchases of Autohome roof tents, founded and directed by a true master of adventure. I learned a lot from this formidable expert.

I personally used several Autohome models. I do not think I am “biased”, in saying that Autohome for me is number one. All those who really know a roof tent say so. My favourite tent is a special Overland, the Black Edition version. The reason for this choice is that I cannot stand the early morning lights. When I sleep, I only want the dark, I do not want to find myself in a tent that lets the first light of the morning pass. With Autohome the fabrics are always very thick and protect very well from light. To rest without limits of… light, choose Black tents! They are the best for me.

What do I do in Autohome? Everything that is production and business organization. I do not even have a precise role: I am active in every direction and in every department to optimize production lines. Everyone knows they can count on my help and commitment. Because my mission is to make Autohome run in the best way! To be clear, I could be the field commissioner, trainer, or coach of a football team. Everything must work, productivity must not be slowed down even more when half the world is waiting to receive our tents. We are in a phase of great market expansion and therefore I have the task of understanding what to improve to push further on the accelerator. All without giving up even a detail of our renowned quality. The team must run, play well in each department and be winning; the product must be perfect from every point of view.

Moreover, I have always been concerned with the quality and suitability of the goods and raw materials we receive from trusted suppliers. This often means supporting our logistics activities too, so that everything is planned and carried out according to our plans.

Personally, the tents I prefer are those that remain in shape inside the mirrors, practically all the rigid tents with a Fiberglass roof. For example, even the expandable ones could be, if assembled, however, as the mythical Nino Cirani taught us. He rests the ladder on the front bonnet and the entire structure remains in shape. You can then stop everywhere without any problems. Life is already quite stressful, at least while travelling and on holiday we make sure to keep you relaxed to the fullest!

It was a challenging adventure, at times really hard, but we managed to get the roof tent appreciated all over the world. We have a planetary success, a new way of understanding the freedom to travel. We are proud of this result, even more than the important development of our company.

I remember that at the beginning of our activity there were many problems: in particular, the economic funds available were always few, but thanks to so much determination and desire to carry out our project, we were able to get the company off the ground.

A strategic factor was to decide to take part in the sector fairs: only in Italy more than 10 fairs per year. Every trade agreement we draft was always a win that filled us with satisfaction. However, sometimes we also happened to return to the site disappointed by the poor results. What bothered us morally the most was the fact that some people made fun of us for the “strange” product we offered. There were moments that seemed that we had to cross desert, an arid ground destined to make nothing grow. Other than adventures in the dunes in 4×4… it was us who saw success as a mirage!

Producing the first Maggiolina, then, was not easy. In the early years we did not have the technology necessary to combine the quality of craftsmanship to the speed of production. In short, we were not ready to make huge numbers of tents. I remember that we even cut the windows of the tent one by one, that is, the fabrics with tailor scissors!

I particularly like to remember two episodes that give a good idea of our development. Two parallel Italian stories, one in Mantua with Maggiolina in the land of the Gonzaga and the other in the great Milan, the city that has always been the productive and industrial heart of Italy. There would be many stories to tell, but in particular I remember these two episodes for the meaning they have. So, I always remember a German manager, owner of a large communication agency, who told to me: “You are Italian, therefore in a better place than me who am German. You are more inclined to fun and happiness, therefore more inclined to express creativity and imagination, unlike me who was educated to reveal less of my emotions”. Another episode that I always take with me is the dialogue with an important French manager who told me: “You are Italian so you are good at cooking, so you know that to make a great dish there are many ingredients that must be carefully dosed.”

Also, with regard to memory, it is important to stress the great satisfaction thanks to the collaborative dialogues with the Automotive manufacturers. I did not think I would get that high. A top manager of a very prestigious brand, in one of our meetings, told me: “In Autohome you are amazing with marketing.” In the second meeting, another manager at their headquarters added: “We appreciate Autohome very much and we want to continue to spread the story of the roof tent that binds us together”. Episodes of this type repeated several times and continue to happen. For example, another strong satisfaction at a recent Las Vegas fair, where many customers came to our booth saying: “Beautiful design, you can see that it is an Italian product”. What does my memory have to do with recommending a tent? I think they are consistent with those who are looking for a product that, in tune with the Autohome spirit, guarantees satisfaction, fun, serenity, well-being and, above all, freedom.

Suggesting a specific tent is not easy. Exactly like a father who has to say if one child is better than another… The personalities are quite different. The family values they interpret are important. If you choose to stay in the great Autohome family, you will certainly be satisfied, because those values are in every tent.

I’ve always had a great passion for travelling and having adventures, for exploring new territories, in particular I love to know far-away cultures and customs. With a similar anticipation, where did I go to work? Of course, in the Autohome Export Office! It was a great satisfaction for me to join the company team and the very office where I wanted to be committed to.

It allowed me to reach this goal, especially my ability to manage different languages: I have a degree in languages, and I speak English, French, Spanish, and Chinese. I learnt the extraordinary Chinese language, complex but fascinating, directly in the city of Chongqing where I studied for about 2 years. A fantastic experience, where I learnt a culture rich in contrasts and full of wild landscapes to discover.

You certainly understood: in Autohome I am perfectly at ease. In fact, I can continue, while working, to fuel my passion for geography and ethnography, discovering different cultures and speaking with customers of many nationalities. I learn their way of thinking and their behaviours. Many different people, but all united in the positive judgment on Autohome roof tents.

Autohome quality is… transnational! It has no borders. This is also why it is not easy to say which tent I prefer. When travelling I want to have a practical tent and no problems: therefore, my tent for the roof of the car must be the easiest to open and close, the most stable and safe, considering that you sleep about 2 meters from the ground. However, I would like to give you some advice: it is better to have a roof. A peace of mind that makes travelling even smarter. Now I know what you’re thinking, and I tell you that you’re right: for me the top is always Maggiolina! Any model is fine, but it is important to have the handle to open and close the tent. That gesture for me is a real symbol: I am travelling, I am free, I am myself.

Sometimes I seem to exaggerate, but every day I would like to do my job in Autohome better. I think it is the result of the climate that we live in the company, where everyone wants to give their best, first of all because we love and respect the product we make.

Where do I do my job? My activity takes place in the fabric tent assembly department. My colleagues and I are in charge of assembling fabric tents, as well as scrupulously checking the quality of materials.

It is a real pleasure for me to participate in creating these tents, still today after 5 years since I have started working for Autohome.

It is always a thrill to think that the tent I am about to check is the same version Nino Cirani used in his ventures. For me, the adventure of Cirani is an extraordinary story, the reference for every travel-adventure enthusiast, masterfully told by the wonderful images it gave us.

I can tell you that the scale reproduction of the Defender 110 by Cirani, purchased in a model shop, is always on my home desk. It is true, the mythical Aziza is located instead at the Turin car museum, together of course with the Overland that stands on the roof. Sooner or later, I am going to see this vehicle, which for me is more than a means of transport: it is the symbol of a philosophy of life.

I have been part of the Autohome staff for several years and I mainly deal with the construction of fiberglass shells. In truth, I also have another task, which I am very proud of – I am the “Master of keys” of the company. What does that mean? With my team we work on the real “heart” of the tents, that is, the opening and closing mechanisms.

We are liable for connecting the base of the tent with the roof, the most delicate phase of the entire construction, which requires experience and special attention. A roof tent is characterized by its ability to open and close quickly… and it is on this point that quality really makes the difference! As it happens, Autohome tents became so famous and appreciated for the quality of these mechanisms. They always work and do not give you any trouble. There are three systems of crank openings for Maggiolina, two with gas springs for Columbus and four with gas springs for Airtop.

All systems are guaranteed for five years. Tested mechanisms of total reliability consolidated in more than 60 years of history. It is consistently reported in our advertising because we invite those who want to buy a roof tent to check how these mechanisms work. In unreliable tents, breakages (in every way!) start from here… For the sake of completeness, I would remind you that there are also folding opening systems for fabric tents. Devices that are assembled and controlled by other colleagues of mine. About “companions of adventure”: in the company they call me “wild” because I am always to help in other departments when they need it most, especially just before the summer season, when the requests are very high.

These are times when you say, what am I doing here? No issue. Working at Autohome is challenging and sometimes I feel like I am having an adventure. It is nice to work in the environment of travel and holidays, but you cannot help but think that it is not… your holiday!

What tent to recommend? Choose instinctively the one that attracts you, the one that you feel you adopt as your own. Autohome tents are all beautiful and all work great. That is why many people want them and then it happens that you have to wait a while. But even this problem can be solved: book them in time!